NOTE: Photo Bucket website has gone to a fee paid service and the pics have been omitted from 3rd party hosting.

Here is a link to Google Drive that will allow you to view the pics.

These will not be in order as how I posted them in this thread. You will have to arrange them in order yourself.

It should point you in the right direction though.

Click

Google Drive

This project has been at the back of my mind for the past couple of years (Thanks for the heads up KaiserM715).

Well, I finally decided to commit some time to it.

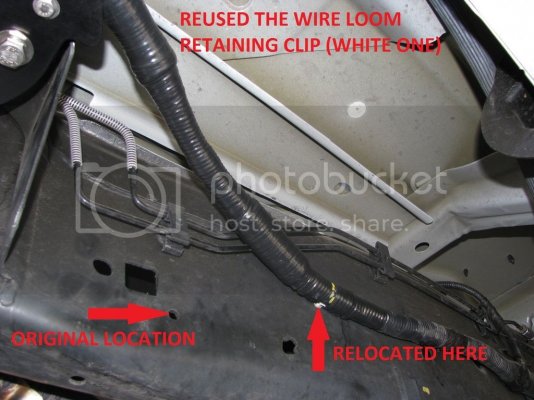

I went out to take a look up underneath the truck to see what I could engineer.

Then I gathered up some measuring tools and created a rough sketch for a relocation bracket.

This is what I conjured up.

Pics will show where I started and the stage that I am currently at.

Please be patient with me as it is not yet completed.

But stay with me as I update the process in the coming weeks.

Taking measurements and creating a sketch.

Ordered the material (7075-T6) 3/16" thickness.

This is a strong alum alloy with good corrosion resistance.

Created an NC program and set the material up on the machine table.

Milled the holes first.

Then switched clamps and milled the periphery.

Then deburred it.

Test fitting the bracket onto the Raptor.

Wheel turned left at full lock to check for clearance (looks good).

I've made changes to some of the hardware that I will be using and will be placing an order for these tonight.

I also need to get the bracket out to plating.

I'm going with hard anodizing,Type III, Class II (black) instead of powder coating.

The location of the bracket which mounts just behind the tire will throw a phalanx of rocks and debris that will soon have any powder coating chewed up.

More to come in the coming weeks.