thanks. got it.PM inbound with number for advice on what NOT to do.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebuilding a 6.2 Engine

- Thread starter PD1744

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

VALVE SPRINGS

Was back at it yesterday. So first off, the Ford 2-valve spring compressor tool did NOT work. I know it was for a modular motor, but hoped they were close enough. They weren't. Do not order this tool. I'll tell you what did work for me, but I'm not recommending that anybody do this. I used the Lisle punch tool to remove keepers though this method would work for removal as well. To install new springs, we loosely installed the opposite rocker shaft on the side of springs we were working on. Meaning if we were on the exhaust side, we installed the intake rocker shaft. That way the rocker arm was offset from the spring. Then took a strong (Snap On) but thin open end wrench underneath the rocker shaft and pried up to compress the spring. Having a second set of hands and the engine not in a truck was definitely beneficial here. This worked great but again, this may not work for your situation, but if you can figure out something like this, it will save y'all from having to buy any specialty tools. I bought 3 and rented 1 just for valve springs. I'm sending the latest one back, and I know that the other two will work for the job.

Bank 1 with fresh springs:

Bank 2:

Pile of old springs:

Was back at it yesterday. So first off, the Ford 2-valve spring compressor tool did NOT work. I know it was for a modular motor, but hoped they were close enough. They weren't. Do not order this tool. I'll tell you what did work for me, but I'm not recommending that anybody do this. I used the Lisle punch tool to remove keepers though this method would work for removal as well. To install new springs, we loosely installed the opposite rocker shaft on the side of springs we were working on. Meaning if we were on the exhaust side, we installed the intake rocker shaft. That way the rocker arm was offset from the spring. Then took a strong (Snap On) but thin open end wrench underneath the rocker shaft and pried up to compress the spring. Having a second set of hands and the engine not in a truck was definitely beneficial here. This worked great but again, this may not work for your situation, but if you can figure out something like this, it will save y'all from having to buy any specialty tools. I bought 3 and rented 1 just for valve springs. I'm sending the latest one back, and I know that the other two will work for the job.

Bank 1 with fresh springs:

Bank 2:

Pile of old springs:

ROCKER SHAFTS

Rocker shaft install was pretty fun. Goes like this:

Lube the cams, rollers, rocker tips, and valve tips with assembly lube. Since these are parts that have already had 150k miles to get to know each other, I wasn't too concerned here.

Turn the engine over so that the cam position on #1 would have the intake valve fully open.

Install bank 2 intake rocker shaft.

Tightening is 3 stage and same for all shaft assemblies:

-Stage 1: 89 lb-in

-Stage 2: 177 lb-in

-Stage 3: 60 degrees

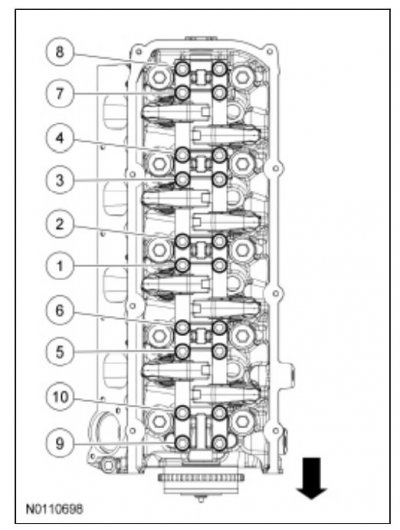

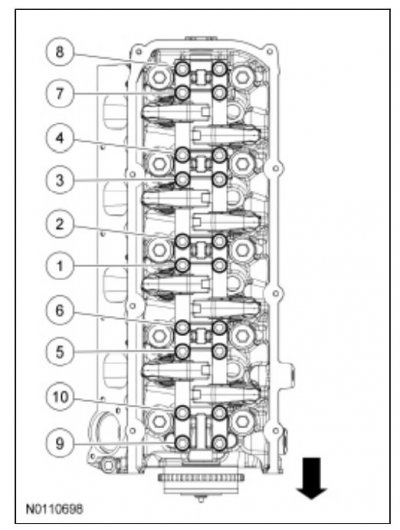

Sequence on intake shafts look like this:

Next, roll the engine over until the exhaust lobe on #1 is where the valve would be fully open.

Install bank 2 exhaust shaft.

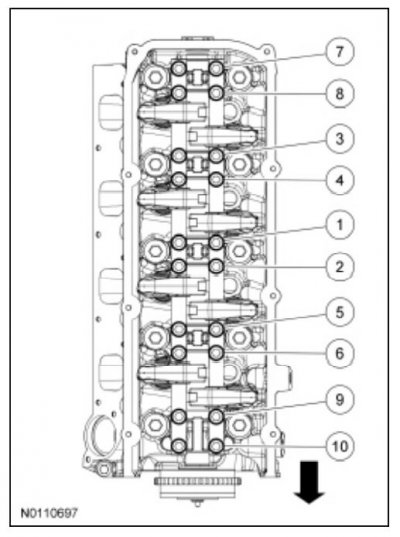

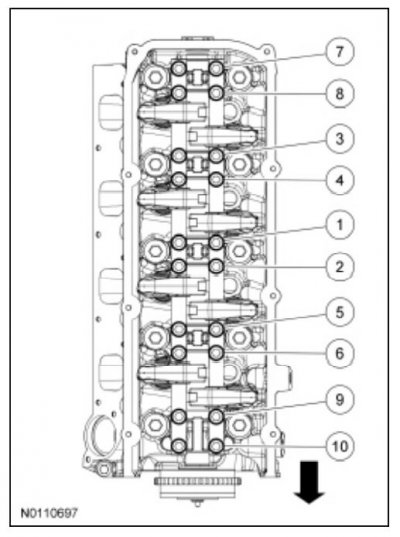

Sequence on the exhaust side looks slightly different:

Bank 1 sequences are just mirrored about the crank plane.

Next roll the engine over until intake on #1 would be fully closed.

Install bank 1 intake shaft.

And finally roll the engine over until exhaust on #1 would be fully closed.

Install bank 1 exhaust shaft.

Done:

So yeah, it's pretty much an engine now. I rolled it over several times by hand and didn't experience anything catastrophic. Every once in a while I would hear this 'click' that seemed to come from the timing set. Sort of plasticky sounding. Not sure what to make of it.

Rocker shaft install was pretty fun. Goes like this:

Lube the cams, rollers, rocker tips, and valve tips with assembly lube. Since these are parts that have already had 150k miles to get to know each other, I wasn't too concerned here.

Turn the engine over so that the cam position on #1 would have the intake valve fully open.

Install bank 2 intake rocker shaft.

Tightening is 3 stage and same for all shaft assemblies:

-Stage 1: 89 lb-in

-Stage 2: 177 lb-in

-Stage 3: 60 degrees

Sequence on intake shafts look like this:

Next, roll the engine over until the exhaust lobe on #1 is where the valve would be fully open.

Install bank 2 exhaust shaft.

Sequence on the exhaust side looks slightly different:

Bank 1 sequences are just mirrored about the crank plane.

Next roll the engine over until intake on #1 would be fully closed.

Install bank 1 intake shaft.

And finally roll the engine over until exhaust on #1 would be fully closed.

Install bank 1 exhaust shaft.

Done:

So yeah, it's pretty much an engine now. I rolled it over several times by hand and didn't experience anything catastrophic. Every once in a while I would hear this 'click' that seemed to come from the timing set. Sort of plasticky sounding. Not sure what to make of it.

Next I installed some miscellaneous parts. Cam position sensors, temp sender, and the other heater pipe:

Noticed I was short a couple of plugs at the back of the cams, so I gotta figure out how to get some of these:

Then started cleaning up these nasty covers but ran out of time:

But yeah, looks like I'm in the home stretch. From here out it's just covers and seals. I'm sure I'm going to encounter a ton of miscellaneous parts that I'll want to replace along the way like those plugs, maybe some O-rings and sensors/senders/switches etc.

Noticed I was short a couple of plugs at the back of the cams, so I gotta figure out how to get some of these:

Then started cleaning up these nasty covers but ran out of time:

But yeah, looks like I'm in the home stretch. From here out it's just covers and seals. I'm sure I'm going to encounter a ton of miscellaneous parts that I'll want to replace along the way like those plugs, maybe some O-rings and sensors/senders/switches etc.

CoronaRaptor

FRF Addict

Looks like its almost ready for @MurderedOutSVT truck!

first off, i claimed first dibs on this.Looks like its almost ready for @MurderedOutSVT truck!

second @PD1744 got any extra nuts or bolts left? i could use a couple.

CoronaRaptor

FRF Addict

You gave up that right when you ordered that used Prius motor for yours.first off, i claimed first dibs on this.

second @PD1744 got any extra nuts or bolts left? i could use a couple.

Well, since @smurfslayer called me out about getting triggered ovet my mpg, I had to do something. I figured there must be plenty of Priuses (priuses? Priusii?) Available for donors.You gave up that right when you ordered that used Prius motor for yours.

As always, appreciate you following along men as well as all the help along the way.

And yes, @The Car Stereo Company definitely called dibs. Hell I think he staked claim before he even actually needed a motor. Foreshadowing perhaps. But @MurderedOutSVT is definitely a lot closer to me.

Oh a couple of other quick tips/lessons learned that could be useful to anybody doing this work. Dabbing grease in the keepers when installing them is definitely money. Also, if you don't have all the plugs in, the piston will run to bottom when you pump it up with air. Even with all of them in, it possibly still could if you're not at TDC. This could be common knowledge to some, but I sure had to figure that out.

And yes, @The Car Stereo Company definitely called dibs. Hell I think he staked claim before he even actually needed a motor. Foreshadowing perhaps. But @MurderedOutSVT is definitely a lot closer to me.

Oh a couple of other quick tips/lessons learned that could be useful to anybody doing this work. Dabbing grease in the keepers when installing them is definitely money. Also, if you don't have all the plugs in, the piston will run to bottom when you pump it up with air. Even with all of them in, it possibly still could if you're not at TDC. This could be common knowledge to some, but I sure had to figure that out.

Similar threads

- Replies

- 55

- Views

- 5K

- Replies

- 8

- Views

- 716

- Replies

- 2

- Views

- 564

- Replies

- 17

- Views

- 2K

Staff online

-

Big BlueAdministrator

Members online

- Trail_Rider

- fat dude

- Sozzy12

- sraz

- Cenz22

- 2018 RR Raptor

- CecilK12

- enve46

- dj30417

- New recaros

- nate_215

- Dee

- Hotsauz

- Anas

- Muchmore

- Nulldetailing

- RxVol

- 8AV8

- GCATX

- stevenstommyboy1

- 62crew

- Tbogo

- stoobymcdoobie

- jaytperry

- SilverBolt

- TXchris

- raptortrav001

- SalvageG1

- EricM

- FlapJack

- The Car Stereo Company

- Hal993

- Pacific Wheel

- Booth9999

- GLT

- pat247

- Waledonald12

- Jmeo

- Big Blue

- Dantana619

- weimer

- BigBlue20

- Five-O Donut Hole

- yotesmc

- Gumby

- optimal

- sj-CHI

- tabvette

- MurderedOutSVT

- ismael8000

Total: 2,487 (members: 91, guests: 2,396)