Visited my engine yesterday. Installed the new chain guide bolt, torqued them to spec, and pulled the grenade pins on the tensioners.

Then went for the last 90° turn on the head bolts. I could have stopped after that. I’m in pretty decent shape but man that was a workout. Only a couple felt like they were about to break though.

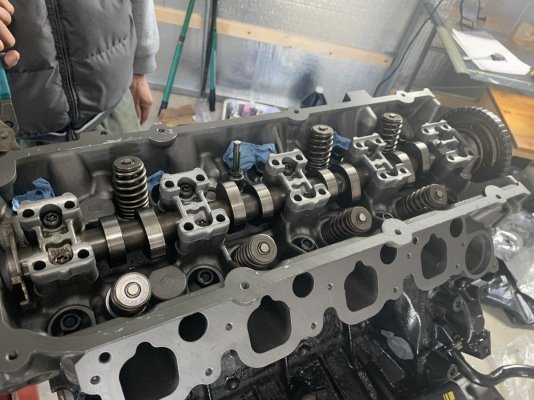

Spent a little bit of time chasing the tips of the rocker arms (don’t know what they’re called) that had fallen off. They are a cup that sits on the ball bearing and held on by this orange sleeve. The part that acts on the valve stem.

No clue how to go about replacing these. I guess I could call the dealer again. You can buy the entire rocker shaft assemblies for a decent price but I really didn’t want to. Thankfully I found all of the missing pieces by some stroke of luck.

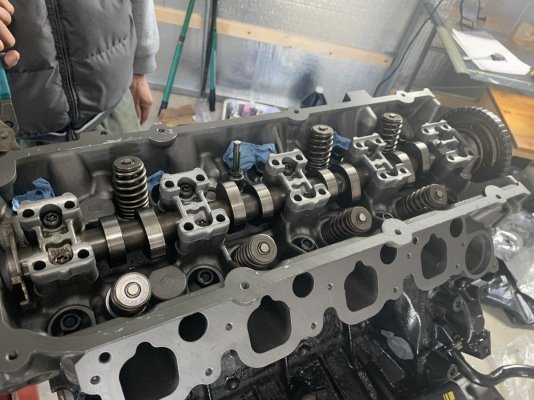

Then took another attempt at changing valve springs but this time with the heads mounted. Quite a few lessons learned here.

Started with #8. Threw the upper plug in and filled it full of air. So the first thing I learned @BenBB is the Lisle tool is incredible at extracting keepers. About as easy as advertised.

However I (YMMV) could not for the life of me get them installed using said tool. The keepers would never seat properly and I became genuinely concerned about damaging something.

I ended up using my other tool, the sketchy compressor, to install them and managed to not loose any eyes or fingers. So that’s cool.

I did #8 and #7 and stopped because I ran out of Melling springs because, if y’all remember, I jacked up the quantity when ordering originally. I did have one new set of OEM springs but opted to just order more Mellings for the rest. I’ve also ordered the crows foot style, Ford 2 valve tool, that I linked earlier that indexes off the cam shaft to try. So hopefully through all my tool trial and error I at least save any of you guys some headache.

Couple other observations with the punch style tool. Not sure how easy it would be to use toward the rear of the engine while it was in a truck. Space gets a little tight back there. Stuff something in the lower oil passages when doing this work as keepers tend to wind up in places you don’t intend them to be at times. Avoided some near catastrophes here.

That’s all. I should have the valve train buttoned up by next visit. I think I’ll end up ordering a new replacement for that cracked valve cover. Need to get the good one and the timing cover cleaned up.

Then went for the last 90° turn on the head bolts. I could have stopped after that. I’m in pretty decent shape but man that was a workout. Only a couple felt like they were about to break though.

Spent a little bit of time chasing the tips of the rocker arms (don’t know what they’re called) that had fallen off. They are a cup that sits on the ball bearing and held on by this orange sleeve. The part that acts on the valve stem.

No clue how to go about replacing these. I guess I could call the dealer again. You can buy the entire rocker shaft assemblies for a decent price but I really didn’t want to. Thankfully I found all of the missing pieces by some stroke of luck.

Then took another attempt at changing valve springs but this time with the heads mounted. Quite a few lessons learned here.

Started with #8. Threw the upper plug in and filled it full of air. So the first thing I learned @BenBB is the Lisle tool is incredible at extracting keepers. About as easy as advertised.

However I (YMMV) could not for the life of me get them installed using said tool. The keepers would never seat properly and I became genuinely concerned about damaging something.

I ended up using my other tool, the sketchy compressor, to install them and managed to not loose any eyes or fingers. So that’s cool.

I did #8 and #7 and stopped because I ran out of Melling springs because, if y’all remember, I jacked up the quantity when ordering originally. I did have one new set of OEM springs but opted to just order more Mellings for the rest. I’ve also ordered the crows foot style, Ford 2 valve tool, that I linked earlier that indexes off the cam shaft to try. So hopefully through all my tool trial and error I at least save any of you guys some headache.

Couple other observations with the punch style tool. Not sure how easy it would be to use toward the rear of the engine while it was in a truck. Space gets a little tight back there. Stuff something in the lower oil passages when doing this work as keepers tend to wind up in places you don’t intend them to be at times. Avoided some near catastrophes here.

That’s all. I should have the valve train buttoned up by next visit. I think I’ll end up ordering a new replacement for that cracked valve cover. Need to get the good one and the timing cover cleaned up.