letsgetthisdone

Full Access Member

That piece of metal locks the axel to the hub. how? That I don't know. but that is what happens. What could go wrong? lots depending how the hub is now married to the axel. In the old days Not all manual lockouts were/are created equal. You are dealing with the same thing. except you can't turn it off. witch will cause more wear to everything from the transfer case forward. and I mean everything. driveshaft, Unjoint, pinion, ring, spider, axel, your lock up, hub. think I got them all. well.... seals.

You're making reliability comments and calling something junk, yet you don't even know how it works...LOL

The RCV is a splined collar, just like the IWE uses a splined collar, which locks the hub and shaft together. Its the "same" as an IWE, except it is longer for full spline engagement, and doesn't move. The components you think it can cause "excess" wear to are designed to be used. Ford offers the truck with AWD mode, so those components are built around the possibility of the truck being driven in AWD a lot or all of the time depending on where someone lives. So having the IWE deleted does not adversely effect anything.

OP, you'll have to get the truck on a lift or off the ground and do some inspecting to see whats going on.

If you have't drivem it much, make sure the RCV sleeves are ocrrectly seated, and pop the little cap out of the center of the hub and make sure the axle nut is tight (this doesn't need to be ugga dugga'ed, you'll break the axle snout, its only 30ftlbs), also check the axle is in all the way-

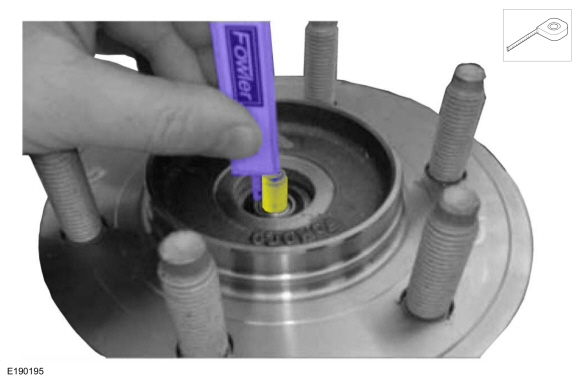

- NOTICE: Measure the depth of the CV shaft threaded end to the inner bearing race (shown in illustration). The minimum depth is 15.5 mm (0.61 in). If the depth is less than 15.5 mm (0.61 in) rotate the CV shaft to clear a binding condition between the IWE and CV splines. Installing the axle nut and tightening without the proper depth of protrusion will result in damage to the IWE .

Measure the CV shaft threaded end to the inner bearing race.