AZ-Rich

Member

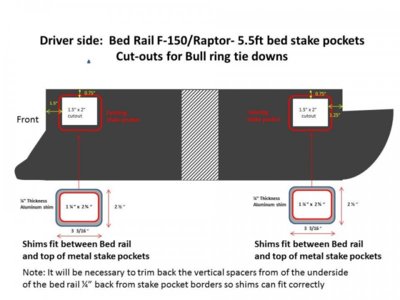

Ok after numerous research attempts on here and other forums I was less than impressed by some of the techniques used to install these particular tie downs, where cutting of the 5.5ft bed rail was required. I installed mine today and found it was really prudent to match the shim thickness and material to best suit the design of the bed rails. I am attaching a diagram of the Drivers side bed rail to illustrate the cuts and position of stake pockets as well as dimensions of the shims. I chose to fabricate a set of rectangular shaped 1/4" thick Aluminium shims which I coated on both sides with rubberized underbody coating.. (any rubberized dip coating spray will do). These shims were designed to be one piece rectangular frames, having an interior opening sized to match the existing stake pockets They provide approximately 1/4-3/8" solid shelve to evenly secure these tie downs onto.

If you look by popping up the corners of the bed rail, you will see that their are a couple of vertical spacer ribs incorporated on the underside of the rail which keep the ABS Plastic rail about 1/4" off of the steel surface near on side and end the pocket sites. You can either dremmel cut these back or us a knife to trim them but you need to clear enough room beyond the perimeter of the stake pocket to accomdate the shims. (about 1/4-3/8")

With the corners popped up slightly you can insert the shim from the bed side and position it evenly over the stake pocket. Then simply mount the Bull Ring tie downs per instruction. You may have to pull up extra hard on the ring when putting the tightening screws in, as the added shim size keeps the starting threads a bit lower . It will defininately tighten down correctly when they do catch. I used blue loctite on the threads as an added security.

This way the bed sits exactly as is was designed and you have a solid foundation with the surrounding aluminum shim and there is no distortion of the Bed rail around the tie down units once they are tightened down.. I think aluminum versus ABS plastic is a far better solution to give a safe, optimal rigidity to the tie down. AZ~Rich

If you look by popping up the corners of the bed rail, you will see that their are a couple of vertical spacer ribs incorporated on the underside of the rail which keep the ABS Plastic rail about 1/4" off of the steel surface near on side and end the pocket sites. You can either dremmel cut these back or us a knife to trim them but you need to clear enough room beyond the perimeter of the stake pocket to accomdate the shims. (about 1/4-3/8")

With the corners popped up slightly you can insert the shim from the bed side and position it evenly over the stake pocket. Then simply mount the Bull Ring tie downs per instruction. You may have to pull up extra hard on the ring when putting the tightening screws in, as the added shim size keeps the starting threads a bit lower . It will defininately tighten down correctly when they do catch. I used blue loctite on the threads as an added security.

This way the bed sits exactly as is was designed and you have a solid foundation with the surrounding aluminum shim and there is no distortion of the Bed rail around the tie down units once they are tightened down.. I think aluminum versus ABS plastic is a far better solution to give a safe, optimal rigidity to the tie down. AZ~Rich