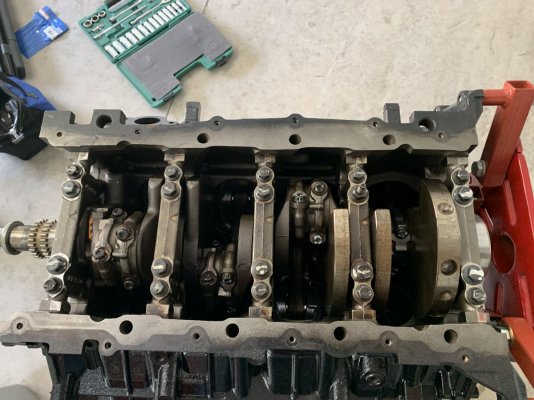

Picked up the engine from the machine shop over the weekend. It's been a long time yes, but again I really wasn't rushing them and told them to take their time. They took it pretty literally. When I checked in last week, he realized he still hadn't knocked the block work out yet, so he was very apologetic and jumped on it right away. Just got lost in the shuffle. No big deal. My goal was to get it to my dads shop and get the block mounted to the stand, however I failed on the latter part as the stand wasn't quite compatible with the back of the engine and will require a little bit of modification. So I had to bail as I ran out of time and didn't get any pictures taken or anything.

My itemized receipt isn't in front of me right now, but I'll try to give you the breakdown best I can:

Block Work

sleeve one cylinder $150

machine block $100

polish crank $40

Head work w/ valve job $250

valve job on second head $50

Sub total $590

Tax $41.30

TOTAL $631.30

Also this morning just ordered:

Oil Squirter Block Off's from Livernois $79.99 + 21.16 Shipping = $101.15

Melling pickup and standard oil pump from Rock Auto $37.79 + 99.79 - $6.88 (discount) + $10.99 shipping + $9.92 tax = $151.61

Running Total

Previous Subtotal $3702.35

Refund for Rods (-$608.55)

Est. Machine shop (-$1000)

Act. Machine shop $631.30

Livernois $101.15

Rock Auto $151.61

Total $2977.86

Hopefully all of the big ticket expenses are behind me. Should have a clear-ish picture of what a project like this would run.

Oh also gave $40 for the engine stand on FB marketplace. Plan to sell for the same when I'm finished.

Items of note

- Machine work came in significantly lower than estimated

- Originally we did not discuss a full valve job on the 2nd cylinder head. They where just supposed to pull vacuum on it to check it, but they ended up doing it anyway. Since we didn't discuss it up front, he only charged me $50 for the work on the 2nd head

- They also replaced all of the valve seals already, so I have don't have to do that now, but also I have some that I don't need. I got some nice Fel-Pro ones off wholesaler closeout, which means I didn't pay a lot for them ($22), but also the window to return them is closed. No big deal.

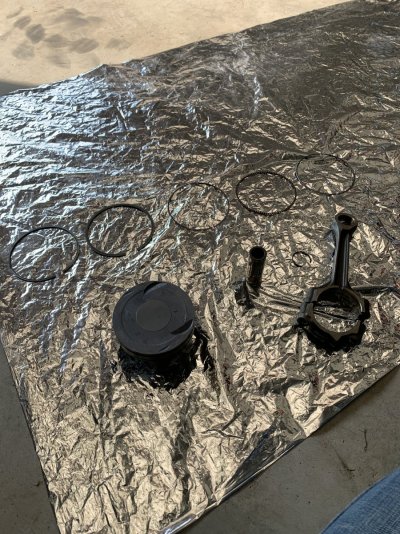

- @CoronaRaptor will be happy to hear that after the block came out of the washer, it already looked really good, but they even offered to shoot it with some fresh black paint for me before bagging it up. Win!

Hopefully this weekend, I can begin assembly. I think it depends how quickly the squirter plugs get to me. Here we go!

My itemized receipt isn't in front of me right now, but I'll try to give you the breakdown best I can:

Block Work

sleeve one cylinder $150

machine block $100

polish crank $40

Head work w/ valve job $250

valve job on second head $50

Sub total $590

Tax $41.30

TOTAL $631.30

Also this morning just ordered:

Oil Squirter Block Off's from Livernois $79.99 + 21.16 Shipping = $101.15

Melling pickup and standard oil pump from Rock Auto $37.79 + 99.79 - $6.88 (discount) + $10.99 shipping + $9.92 tax = $151.61

Running Total

Previous Subtotal $3702.35

Refund for Rods (-$608.55)

Est. Machine shop (-$1000)

Act. Machine shop $631.30

Livernois $101.15

Rock Auto $151.61

Total $2977.86

Hopefully all of the big ticket expenses are behind me. Should have a clear-ish picture of what a project like this would run.

Oh also gave $40 for the engine stand on FB marketplace. Plan to sell for the same when I'm finished.

Items of note

- Machine work came in significantly lower than estimated

- Originally we did not discuss a full valve job on the 2nd cylinder head. They where just supposed to pull vacuum on it to check it, but they ended up doing it anyway. Since we didn't discuss it up front, he only charged me $50 for the work on the 2nd head

- They also replaced all of the valve seals already, so I have don't have to do that now, but also I have some that I don't need. I got some nice Fel-Pro ones off wholesaler closeout, which means I didn't pay a lot for them ($22), but also the window to return them is closed. No big deal.

- @CoronaRaptor will be happy to hear that after the block came out of the washer, it already looked really good, but they even offered to shoot it with some fresh black paint for me before bagging it up. Win!

Hopefully this weekend, I can begin assembly. I think it depends how quickly the squirter plugs get to me. Here we go!

Last edited: