You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Olsen Gen 2 And Gen 3 Raptor Build Thread

- Thread starter Olsen Motorsports

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Olsen Motorsports

Full Access Member

Tore down the BD Lights today! Sending them out for powdercoating

Attachments

-

E3F75E60-EAC4-42DA-9C6D-3867BFFB7777.JPG228.6 KB · Views: 5

E3F75E60-EAC4-42DA-9C6D-3867BFFB7777.JPG228.6 KB · Views: 5 -

181FB6AE-C2D6-4098-ADBC-A6D1EE74115D.JPG262 KB · Views: 5

181FB6AE-C2D6-4098-ADBC-A6D1EE74115D.JPG262 KB · Views: 5 -

C817FDEF-59BB-4139-BE1C-B53CD5EB1C92.JPG177.8 KB · Views: 6

C817FDEF-59BB-4139-BE1C-B53CD5EB1C92.JPG177.8 KB · Views: 6 -

C51D84B1-20AB-4425-9829-133490C9F114.JPG211.2 KB · Views: 6

C51D84B1-20AB-4425-9829-133490C9F114.JPG211.2 KB · Views: 6 -

3E8242FA-FC18-424B-8A86-A9BDF961FF0D.JPG190.7 KB · Views: 6

3E8242FA-FC18-424B-8A86-A9BDF961FF0D.JPG190.7 KB · Views: 6

Olsen Motorsports

Full Access Member

Further inspections on the housings, tons of corrosion on the insides but the seal saved the circuit boards. We are going to put this on our annual service for the truck to tear down and service the lights.

Hit the housings with the vapor blaster, you can see the pitting from all the corrosion from the winter driving, cleaned it right up will treat with sd-50 before we re-install

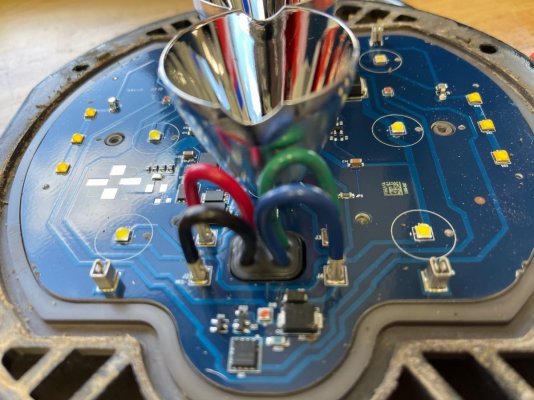

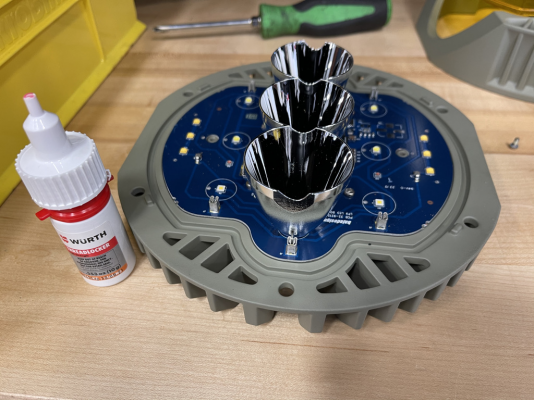

All the boards inspected and cleaned

Stainless hardware UGH. Most of them didnt come out so we will replace with Mil Spec 12 Point hardware. Should make servicing easier

Vapor blasted the inside of the heat sinks as well. Tons of corrosion glad we tore them down!

Hit the housings with the vapor blaster, you can see the pitting from all the corrosion from the winter driving, cleaned it right up will treat with sd-50 before we re-install

All the boards inspected and cleaned

Stainless hardware UGH. Most of them didnt come out so we will replace with Mil Spec 12 Point hardware. Should make servicing easier

Vapor blasted the inside of the heat sinks as well. Tons of corrosion glad we tore them down!

Olsen Motorsports

Full Access Member

Olsen Motorsports

Full Access Member

motoman289

Active Member

looking good!

Olsen Motorsports

Full Access Member

started assembly!

Almost forgot to wipe down the optics before sealing it up! Even if its clean any grease from a fingerprint will show up from the heat

All sealed up, used titanium hardware so there will be no more corrosion on the bolts

Brackets needed a little contrast so went with grey on those to spice it up a little bit

Also re powdercoated the swarfworks light bar in our special Olsen black. Hoping it all goes together and flows when it is all set up! You never know until you see it all together wether you like it or not

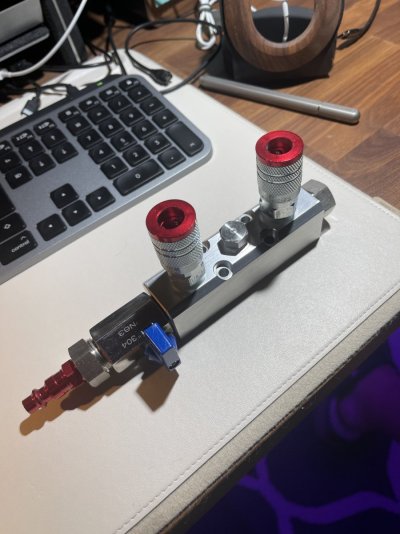

I have to air up and down 3 times a weekend, I have the factory wheels too, the H5265 haltec , have the most grip but also have very little room, I haven't received them yet but the connectors that updownair use, are my next point of call to try, at the moment I have the Astro AI closed chucks on a 4 way hose system, they don't leak. I also finding that the ARB takes a long time to inflate 4 tires from 11 to 38 at the same time, so I have ordered another ARB and I am moving the one from the cab to the bed under the cover case for the retrax, so there will be one dual arb for each side of the truck, also putting a 1 gallon viair tank on each compressor on a custom bracket coming from the cab box link connector, black rubber pipe under the bed lip to a manifold mounted to a builtright panel on each side at the rear, that has a ball valve and a pressure gauge, however I tend to use the dash gauge and control the compressor from the ARB pressure app on max pressure, as it doesn't seem to work well with auto pressure on multiple tires. I will remove the aRB pressure control, as I have a Garmin power switch, which I can use the app or the new tread to control the ARB on or off, I'm told the ARB switch is only a few amps compared to the main draw of 50 ish amps, It should in theory reduce the inflation time when the second is installed currently 20 mins on single , airing down all four is 6 or 7 minutes, time to mount a flag etc. I also have the swarfworks rear winch and couldn't be happier, I have the 12s platinum. Please keep updating this, sorting out a simple on off air system is my holy grail, along with some sort of slide to get the pro eagle in and out of the truck bed.So the issue I’m running into now is the connection to the tire valve itself. We are running factory true beadlocks and the stems are super recessed.

I really want to use closed flow sleeve locks over swage locks but looking at CAD files there isn’t going to be enough room there to engage the lock.

Air tight no leak seal is the goal. Clip on’s suck big ones. Hate to build such and expensive system and run a cheap end on the hose [emoji2363]

Anyone have a better solution they can point us towards?

I’d rather sell the truck than take apart 16 beadlock wheels to change to a longer stem [emoji2959]

Sent from my iPhone using Tapatalk

Olsen Motorsports

Full Access Member

I have to air up and down 3 times a weekend, I have the factory wheels too, the H5265 haltec , have the most grip but also have very little room, I haven't received them yet but the connectors that updownair use, are my next point of call to try, at the moment I have the Astro AI closed chucks on a 4 way hose system, they don't leak. I also finding that the ARB takes a long time to inflate 4 tires from 11 to 38 at the same time, so I have ordered another ARB and I am moving the one from the cab to the bed under the cover case for the retrax, so there will be one dual arb for each side of the truck, also putting a 1 gallon viair tank on each compressor on a custom bracket coming from the cab box link connector, black rubber pipe under the bed lip to a manifold mounted to a builtright panel on each side at the rear, that has a ball valve and a pressure gauge, however I tend to use the dash gauge and control the compressor from the ARB pressure app on max pressure, as it doesn't seem to work well with auto pressure on multiple tires. I will remove the aRB pressure control, as I have a Garmin power switch, which I can use the app or the new tread to control the ARB on or off, I'm told the ARB switch is only a few amps compared to the main draw of 50 ish amps, It should in theory reduce the inflation time when the second is installed currently 20 mins on single , airing down all four is 6 or 7 minutes, time to mount a flag etc. I also have the swarfworks rear winch and couldn't be happier, I have the 12s platinum. Please keep updating this, sorting out a simple on off air system is my holy grail, along with some sort of slide to get the pro eagle in and out of the truck bed.

Thats a great idea! How long does it take to air all four with the twin compressor setup? I might add another one as well!

Similar threads

- Replies

- 13

- Views

- 2K

- Replies

- 0

- Views

- 239

- Replies

- 16

- Views

- 5K

Staff online

-

Big BlueAdministrator

Members online

- neovenator

- bigrig

- Kev_nell199

- XCReapor

- Sharpie69

- ThreeSixT

- GU3R086

- MOTOR10

- smurfslayer

- IHAVETWO

- mrdci

- Suren27

- CleverGirl_

- veritas

- GCATX

- DFS

- 4151zero

- Barrymahcockiner

- mprice1234

- Braaaaptor

- AzRim

- 23Raptor23

- Rhy86

- Peterb

- Baja Mode

- DaveInMn

- WatFam

- Old-Raptor-guy

- n8sbroken18raptor

- steel996

- randomname3

- Dev

- FJohnny

- ToadSmasher2K1

- holymountain

- abelardoo_12

- Arizona Free

- scorched88

- RRR19-Mike

- Big Blue

- grif82

- High Sierra

- Dnovakovic4

- letsgetthisdone

- Rapid990

- iwish97

- kbexit

- badm0t0rfinger

- Dudebrodude

- 2020NOOB

Total: 2,476 (members: 58, guests: 2,418)

Forum statistics

Latest posts

-

-

motor swap with body on

- Latest: The Car Stereo Company