You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Naturally Aspirated 6.2L Build

- Thread starter bubblehead93

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Muchmore

FRF Addict

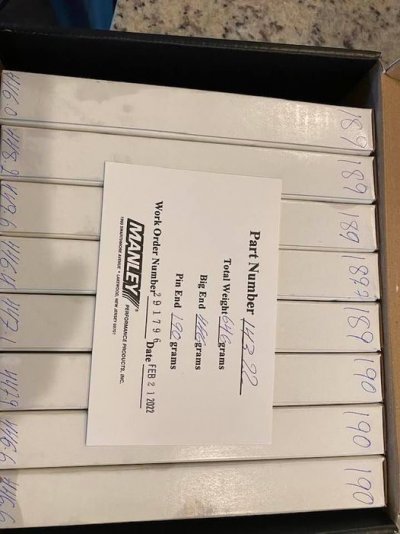

We have connecting rods... or at least they finally shipped from Manley, be here tomorrow... hooyah... need to wrap up my current project so I can get back into engine building....

Interesting picture of connecting rods you have there. This engine build may not work out for you aftrerall

bubblehead93

Full Access Member

bubblehead93

Full Access Member

bubblehead93

Full Access Member

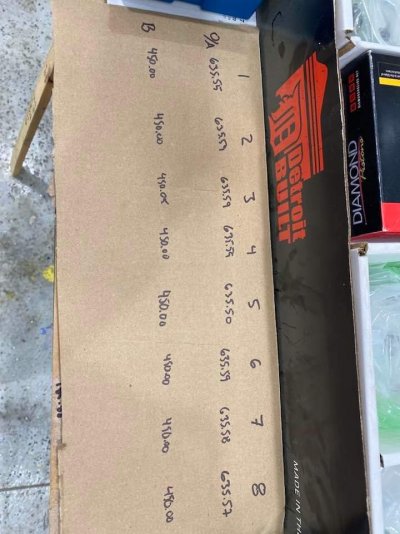

Need to get these balanced and off to Cody Dawson… to balance the rotating assembly…

Awesome thread. How come these engines are getting so rare now? I thought you could just pull a block from a 250?

bubblehead93

Full Access Member

it’s about expectations… any remanufactured motor is likely to be a super duty, the f150 motors are a nitch application… plenty of 6.2 blocks out there… I’m also a 4.6 4V guy, if you want a motor, find the block you want and build a motor… not a criticism, but the raptor community, by and large, want drop in motors, in the 03-04 cobra world as well as the Mustang HPDE/track world, folks build their own motors (or have someone build one)… they are 20 year old cars, no more crate motors (unless your dropping in a coyote), the 1st gens are starting to age into that same situation… unfortunately the pandemic has impacted alloys used in high performance applications so it can take awhile to get parts, 6.2 or 4.6…

Last edited:

bubblehead93

Full Access Member

View attachment 318483

balancing some pistons... Slow and steady...

Update: Mission complete balancing pistons, pistons and wrist pin assemblies all 626.4 grams (+/- 0.02 grams). Target was to get them within 0.1 grams of each other. On average I had to remove 0.14 grams from six of the pistons. In any event, one task done. DCR is working the cams. Cody Dawson has started working the heads. Still waiting on Manley to ship the connecting rods. Slowly coming together.

I never really explained this process, all your doing is finding the lightest piston and then you remove material from the inside edge of the piston skirt from all the other pistons until they match, mostly around wrist pin bosses, essentially just chamfering the machined edge... you remove material, after a piston or two you get a feel for how much material to remove to achieve the required number of grams... you trying to get them all within +/-0.1 grams of each other... with high quality aftermarket pistons they all start pretty close to each other... it is funny though, with pistons and rods, if you get 8, 7 will be close to each other, 1 will always be an outlier... hopefully it's not the lightest one... lol

bubblehead93

Full Access Member

i'll type up a rod balancing simple how-to tomorrow... after I finish balancing all the rods... sigh...

bubblehead93

Full Access Member

Similar threads

- Replies

- 29

- Views

- 4K

- Replies

- 17

- Views

- 2K

- Replies

- 11

- Views

- 2K

- Replies

- 14

- Views

- 1K

- Replies

- 2

- Views

- 514

Members online

- schmitty

- HookEm

- wyomingraptor

- thebigm29

- Mystic_2003

- shigman

- Jeddler

- javiles

- deadserial

- Pyro3601

- CancerDoc22

- Deft_Phenom

- Sage

- Fender150

- TheFuriousFatty

- nmp1

- vortexkidd

- mrrobinson53181

- insangsong78

- AggieRaptor

- cfmistry

- stoobymcdoobie

- Shane361

- Solidred

- Nyamg

- Derrick Hernandez

- Frogger22

- Cody Templeton

- Jhollowell

- Bullfrog666

- Ryan C

- mtday85

- Geforce

- grleon65

- JohnyPython

- F-22OR

- FGHT ON

- Nick@Apollo-Optics

- plindo

- ToadSmasher2K1

Total: 2,333 (members: 42, guests: 2,291)

Forum statistics

Latest posts

-

We have to talk about CV Axles.....

- Latest: TheFuriousFatty

-

18 Raptor - MyView - Oil Pressure

- Latest: Zeusmotorworks