I did notice yesterday that it was idling kinda ruff. I had a pretty bad miss fire awhile back and it went into limp mode when I hammered it in sport mode going about 75mph. My wife’s land rover has been at the dealer since Christmas Eve, and I don’t want to go thru that, so I’ve been holding off until it is undeniably making the noise.

Sent from my iPad using Tapatalk

That noise you hear that is ticking at cold start is likely the lifters not the cams directly. Can be common but not good, however if you hear it from one bank to another their is something worth opening it up and having a look to find what it is.

The oem filters as well as most quality non oem oil filters like Amsoil, etc, use an anti drain-back and identical bypass spring pressure to be able to meet the oem spec. It is the cheap version of certain oil filter brands that will be the issue 99.9% of the time.

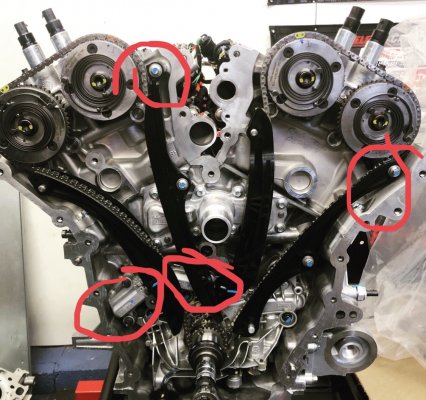

The cam phaser issue is a multi part problem.

1- new phasers have just been updated and released and they I believe are now engineering mark CC at the end. First was CA and then CB, now ends in CC. Apparently they did something to a sticking locking pin and springs. (Ford maybe even updated blinker fluid to help who knows.) [emoji849]

It is our experience that we can help the issues with cam timing issues such as phasers, I take cams rolling aft to positive degrees and with a few other things.

1- a cam grind focusing more on changing duration, and adding a little lift will help a lot due to how these cams are often in an “at rest” position. With zero load on any lobe causing the cam which is at rest at the moment to be lose and actually move it by fingers back and forth These Gen2’s this is heavily pronounced over gen1.

With a DOHC 60 deg v6 cam timing, chain, phaser issues and erratic cam events are very common across all platforms. Because each cam has a neutral or no load position during each of its one revolutions, (x4 cams) it has been known to cause erratic timing events which can and will increase wear on parts such as phasers , possible broken tensioners and guides.

This is something that had been an issue on platforms since variable cam timing was introduced in a 60 degree v block v6 With DOHC. If you added say two cylinders and had a V8 the extra 2 lobes per cam, per bank, would lesson the amount any cam is at rest because your keeping load on the cam from adding another set of lobes that will be loading a lifter and limiting the at rest position by a good amount to make a difference.

One solution would be to delete VCT? In my opinion, in a truck, you lose everything that makes these what they are and a ton if not all the HP TQ in the low end is then lost. That would suck, not fun and the ecoboost kicks a$$ because of the fun from the amount of insta-torque and low end power it can generate. You’d have to keep it wound tight at higher rpm to feel the same and raise rev limiter IMO to 8500rpm.

In lieu of deleting, I’d prefer to limit VCT movement. I would do this with the addition of a simple regrind of the oem cams and add like 20 deg duration on exhaust cams and 5-10 on intake cams roughly. Not only will you have something to make more power now, but you are helping the issues with the erratic timing and killing two birds with one stone. Plus the wife would understand easier that your fixing the issue, not buying cams.

[emoji2936][emoji3061]. Yeah, my wife, she knows my playbook by now. lol

With the cams ground, my suggestion would be to pin or limit the 4 cam phasers accordingly based on the amount you changed duration. So basically if you add 20 degrees you pin or limit 15-20 degrees of the cam movement.

Generally we will limit cam phasers by the amount of duration we add and when we start really adding lift and or real duration we have to limit VCT usually deleting it. Too much stress on phasers is bad.

With the ecoboost (gen1 and Gen2) the intake cams have a whopping 60 degrees of variable cam movement already. We for sure consider that as much as we would like to see and 60 degrees of movement is probably already causing added wear on the phasers which is seen by the mileage many are having issues at. Now throw into the mix their is an added erratic cam that’s yanked from being smacked every one of its revolutions for a millisecond and timing events are thrown off and from the rather long and frequent amount of time the cams have no load on them. This is and will exacerbate and increase wear on phasers and all parts.

Particularly with the worlds absolute worst timing chain tensioners that have almost zero consistency and I think ford is whacked for even using them or thinking of it. Use the GT500 style tensioners and be done! Wish they fit

By grinding the cams and changing the duration, you are now changing how large and where base circle and center lines are. This can greatly change how often and how long each cam is not loaded and therefore limit the window for erratic behavior by cutting down how often these cams have no load on them and literally are lose in that position and this all cuts that amount down by a fair margin. Tons of issues which cause V6 DOHC’s problems with timing, and I could show you if you and you’d hear the popping noise when we see a cam get to its neutral position. and you can hear when each cams at rest if you were next to me in the shop and they make little popping noises when the lifter on a bank sees no preload on them. By limiting the movement of the cam phasers you are putting less stress on them, and by helping limit

(as much as possible) the amount that these irregular and wearing events happen will prolong life of the timing chain drive assembly.

By limiting 10-20 of the degrees of movement will go a long way with adding to the longevity and preventable accelerated wear on the parts within the components. Gen1 cams due to valve train type and lobe design are naturally at rest less often than Gen2 roller rocker style lobes and lifters.

Next issue, the tensioners. More on this later, but tensioners must be upgraded from the crap that’s in these now. We will be working on a full timing kit with all parts that are not only stronger and last longer, but allow options as to what you do with VCT or how much it is able to move.

Quick look inside phasers. These are the smallest phasers two major manufacturers we have been working with for 2-3 years on the Gen2’s and they both first said they were shocked at the small size off these phasers and probably the smallest phaser they had ever seen across any platform.

Sent from my iPhone using Tapatalk

Last edited: