I would REALLY like to know how you get that much lift out of a stock cam!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GEN 2 Bolts shearing—High Pressure Fuel Pump

- Thread starter Proflyer

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

New recaros

FRF Addict

It sounds more like the pump is hydraulically locked. Not sure if there is an external or internal by-pass or pressure regulator. I bet it breaks when you chop the throttle, injection backs off and pump pressure goes really high causing a locked pump. Investigate the pressure regulation.

Hi all, had exactly the same issue -- also Twice -- under recall. These bolts are special "stretch bolts" and can not be used twice or be replaced by "ordinary bolts. Had no issue anymore when they ordered the bolts and pump from Ford. These Bolts have some sort of "elasticity" Possibly the temptation to use "normal" available bolts that are not "stretchable" can be an issue . That is what i learned ..

SilverBolt

Hired Gun

Two possibilities. #1 the tech over torqued the bolts. #2 defective bolts. Possibly do to hydrogen embrittlement. If a bolt has HE it will appear to look normal. Once torqued in place they will fail under load. It may not happen right away. The minimum test time for HE is 24 hours torqued in place.

Post a photo of the broken end of the bolt. I may be able to tell from the photo what caused the failure.

Post a photo of the broken end of the bolt. I may be able to tell from the photo what caused the failure.

Two possibilities. #1 the tech over torqued the bolts. #2 defective bolts. Possibly do to hydrogen embrittlement. If a bolt has HE it will appear to look normal. Once torqued in place they will fail under load. It may not happen right away. The minimum test time for HE is 24 hours torqued in place.

Post a photo of the broken end of the bolt. I may be able to tell from the photo what caused the failure.

Is hydrogen embrittlement a result of hot dip galvanizing, electroplating with zinc, etc?

First I heard of it was on this thread and then the next day noticed a grade of bolt I planned on issuing couldn’t be HDG.

So full circle, that bolt kinda looks like it could be stainless. I could definitely be wrong on that though.

No news yet. Yes they used the right (new) bolts each time. He even showed it all to me the second round.

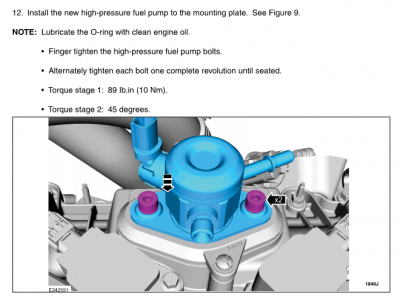

I’ve asked if I can get pics of the bolts once they pull them out. Service advisor is going to see if the tech still has them. Ford wants them to tear into the head to see what’s up. If they can’t find an obvious issue, they may just replace the head. Odd the original bolts held for 55k. Then phaser job (new bolts, same pump) and breaks. New bolts and pump and breaks again in 200 miles. The tech rattled the torque sequence off to me and showed me the attachment above, so I trust they’re doing that right. More to come.

I’ve asked if I can get pics of the bolts once they pull them out. Service advisor is going to see if the tech still has them. Ford wants them to tear into the head to see what’s up. If they can’t find an obvious issue, they may just replace the head. Odd the original bolts held for 55k. Then phaser job (new bolts, same pump) and breaks. New bolts and pump and breaks again in 200 miles. The tech rattled the torque sequence off to me and showed me the attachment above, so I trust they’re doing that right. More to come.

SilverBolt

Hired Gun

Correct. Fasteners with a HRc of 25 and higher are at risk of HE when they are electroplated. The electroplating process can induce hydrogen molecules into the parts. Any electroplating can do this (zinc, nickel, galvanize, etc). A post plating bake can help to reduce the risk of HE but will not eliminate the possibility. The higher the Rockwell the greater the risk.Is hydrogen embrittlement a result of hot dip galvanizing, electroplating with zinc, etc?

First I heard of it was on this thread and then the next day noticed a grade of bolt I planned on issuing couldn’t be HDG.

So full circle, that bolt kinda looks like it could be stainless. I could definitely be wrong on that though.

Similar threads

- Replies

- 9

- Views

- 554

- Replies

- 0

- Views

- 510

- Replies

- 10

- Views

- 3K

- Replies

- 41

- Views

- 8K

Members online

- ToadSmasher2K1

- Matty The Baddy

- Sage

- Reaper308

- GG17

- optimal

- LOUSCRW

- dnas123

- NickyF25

- jAKe47

- OICNW-Rob

- QCRappy

- MotorsportsAustin

- berto2323

- KustomAF

- dj30417

- hdvvraptor

- shmirgin44

- P4SHOCAT

- beachcomber

- mikemxbike4

- cfmistry

- Inprogress

- sbradle4

- GCATX

- GAMike

- redsmoke

- Bozz

- MurderedOutSVT

- Dinoman

- Gumby

- veritas

- MeFryRice

- hunz

- Badboy4fun_wa

- joehokie

- marcus6867

- Budget1

- EricM

- Sozzy12

- The Car Stereo Company

- dsg2003mach1

- Arsenal89

- MrVeteran51248

- intedinator

- Burrus

- SterlingE55

- MEIRONMAN207

- SVTCQ

- G3Rap

Total: 3,861 (members: 90, guests: 3,771)

Forum statistics

Latest posts

-

Cars and Coffee Raptor take over.

- Latest: MotorsportsAustin

-

-