Okay, here we go........

I went to the southside location of Peerless Spring here in Edmonton at 7:15 am sharp and was told I wouldn't be allowed in the shop to see my work progress or to take pictures. So I told the guy to go *&$# himself and left.

Went to the Peerless west location and met with TJ the service writer and Phil the shop foreman, they called over to the main office and got permission for me to do what I wanted as far as pics went. After speaking with the main district manager, I was surprised to hear the first guy told them I was pretty much requesting to film a documentary. What an idiot, but anyways here comes the results:

When I did my top perch adjustment the front height was this:

The rear was here:

They measured the side to side variance on the height of the truck at 42.75 right and 43 inches left.

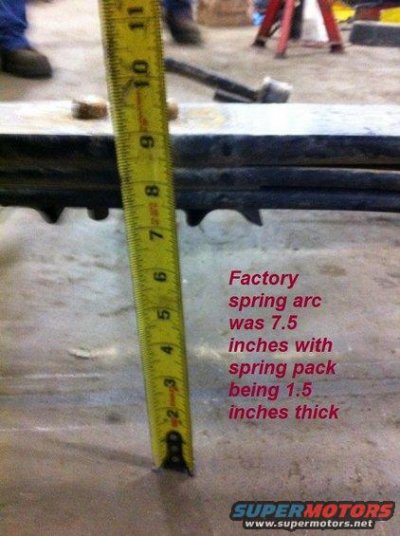

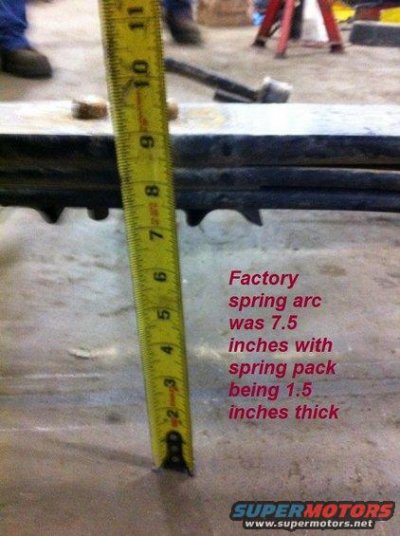

They disassembled the rear of my truck, flipped over the factory leaf as is and we measured the factory leaf pack as 1.5 inches thick and the overall arc from main leaf to ground at 7.5 inches:

Next they took the packs apart and did a cold arc to the right main leaf so it matched the left to equal the height out side to side.

I didn't get them to lift it any higher as I wasn't trying to lift the truck very much and the added rigidity to the spring pack would be enough to satisfy me.

The factory main leaf is .437 inches thick and the second leaf down from the factory comes in at .401 inches thick. The base leaf wasn't measured but it looked like .650 or damn close to it cause the factory pack did measure out at around 1.5 in total.

So he rips apart the factory packs and we decide to go with a .449 inch "add a leaf" so I can boost the support as much as possible to resist axle wrap. Phil the shop foreman says that the difference is ride quality won't even be noticed. I though "yeah sure, I'll believe that when I feel it" cause I don't think Phil realized just how nice the ride is in a Raptor!

I got him to install the new secondary leaf as close to each eyelet as possible without causing issues with bind or noise and I was pleasantly surprised to see them chamfer the edges to resist binding and to take away a potential stress point.

I told these guys I fully intend to jump my truck 5 feet in the air at 100 mph this spring, so unless they wanted it in their lot one morning in pieces please keep this usage in mind.

this is what they did:

The leaf pack netted out at 2 inches thick and the arc only increased like 3/4's of an inch.

At this point I want to say that I was trying for a 2 inch height difference front to the rear. It came in 1/4-1/2 inch low.

If you want factory height (give or take 1/2 inch) with the lift block in place, you could leave the cold arc alone, don't do one. Add a .449 inch secondary leaf the way it's shown and throw the old factory second leaf in the trash bin.

This is what I wanted:

Total cost was $580 plus tax, total labor was 1.5 hours per side plus new u-bolts plus the leaf material.

So if you take the labor out and compare parts to parts, this was a $280.00 job versus $1300-1400 leaf packs you see being sold.

I paid the guys, told them I'd see them later on today for my retorque and set off on a 300 mile round trip to drop my daughter off at a friends house for the weekend.

On the way back I hit some pretty sketchy gravel roads out in the Edson area and for those that don't know it some of these roads are like simulating a desert crossing LOL.

Washboard, you know that ripples effect on gravel that is just brutal to hit? Lets be honest here I would just about get thrown sideways hitting that shit at any type of speed on the factory springs. Yesterday? I was going down these roads at 70 mph and it was like I was floating over them!

Phil was right, the spring thickness did nothing to ride quality and I will tell anyone right now to throw caution to the wind and do this ASAP.

I got home and grabbed the girlfriend

, then asked her if she wanted to go for an hour ride on some gravel to make sure todays retorque goes good.

First thing she says? "how come the truck is so smooth? It doesn't seem to want to spin out all the time" When your girl notices ride quality? You're on to something.

I finish the "break in" on the springs and I know the moment of truth is here.

I get back on the pavement, come to a complete stop, shut of the traction control and pin the truck to the floor......

The rear plants perfect, no shutter, no bouncing, No leaving twenty individual one foot long black marks, the truck has ZERO wheel hop. It actually felt strange to be able to launch without feeling like I was about to spit out a driveshaft.

I will have to add a side view of the truck cause at this height it looks imposing as hell. It's 5am and still dark, but I have Raptor fever so I'm wide awake at the key board.

I also want a video of the lauch cause there will be people calling ******** on these results and I want no chance of anyone second guessing anything I've written.

The ride is better than factory, the stance is perfect, no wheel hop and I kept over $1100 in the bank for my wheel upgrades.

All in all? I nailed it

Jeff

, then asked her if she wanted to go for an hour ride on some gravel to make sure todays retorque goes good.

, then asked her if she wanted to go for an hour ride on some gravel to make sure todays retorque goes good.