FordraptorHero

Well-Known Member

- Joined

- Dec 24, 2015

- Posts

- 519

- Reaction score

- 321

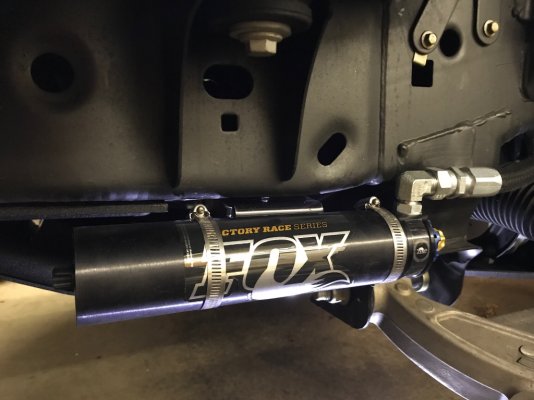

As a complete worthless **** when it comes to installing mods I am trying to take on the task of installing fox 3.0 coilovers. Unfortunately after browsing the forum I could not find any videos or write ups directly representing the installation. However I did provide all the sources I found helpful below for anyone in the same situation as me.

This thread is intended to get as much information about installing fox 3.0's out there as possible for noobs like my self. If anyone has any other helpful resources,personal experiences, videos, or tips on how to make this process smooth as can be please provide them below and I will add them to this thread.

My big question: where and how to properly mount the reservoirs, Any pics or explanations would be great. TY! hope this helps someone out there.

Source 1) Icon 3.0 coilover upper control arm installation

- Gives all necessary tools and parts needed to do the job.

-------> Link http://www.fordraptorforum.com/f9/i...l-arm-skid-plate-installation-write-up-20927/

Source 2) Torque specs( FORD RAPTOR FORUM)

----------> LINK to torque specs for specific bolts in front suspension.

http://www.fordraptorforum.com/f39/torque-specs-11451/

Source 3) VIDEO SHOWING HOW TO REMOVE IWE's

This video isn't directly related to the installing and removing of shocks, however it provides some helpful information for removing the stock shocks.

https://www.youtube.com/watch?v=AlHDws6yFP0 ------> Link TO VID

Source 4) Installation instructions from fox

-----> Link to instructions https://www.ridefox.com/dl/truck/manuals/605-01-071-revb-co-raptor-web.pdf

also any info on how to adjust and get the right ride height and perfect the tuning would be extremely helpful as well

This thread is intended to get as much information about installing fox 3.0's out there as possible for noobs like my self. If anyone has any other helpful resources,personal experiences, videos, or tips on how to make this process smooth as can be please provide them below and I will add them to this thread.

My big question: where and how to properly mount the reservoirs, Any pics or explanations would be great. TY! hope this helps someone out there.

Source 1) Icon 3.0 coilover upper control arm installation

- Gives all necessary tools and parts needed to do the job.

-------> Link http://www.fordraptorforum.com/f9/i...l-arm-skid-plate-installation-write-up-20927/

Source 2) Torque specs( FORD RAPTOR FORUM)

----------> LINK to torque specs for specific bolts in front suspension.

http://www.fordraptorforum.com/f39/torque-specs-11451/

Source 3) VIDEO SHOWING HOW TO REMOVE IWE's

This video isn't directly related to the installing and removing of shocks, however it provides some helpful information for removing the stock shocks.

https://www.youtube.com/watch?v=AlHDws6yFP0 ------> Link TO VID

Source 4) Installation instructions from fox

-----> Link to instructions https://www.ridefox.com/dl/truck/manuals/605-01-071-revb-co-raptor-web.pdf

also any info on how to adjust and get the right ride height and perfect the tuning would be extremely helpful as well

Last edited: