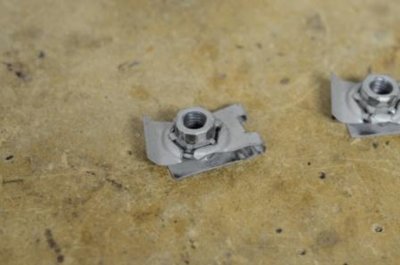

like a lot of you, i tend to use power tools when i can. i had to pull my lower skid while i was working under there and ended up breaking the nut clips that were used to bolt it in from the factory. this meant that i couldnt get my lower skid off because the bolt had threadlocker on it and both the nut and bolt were turning at the same time. after spending some time scratching my head and cussing, i found out how to get it off. first off, make sure you have the right wrench. the first time i tried this, i had my gearwrench and it successfully stripped the corners of the nut, making it harder with a different wrench. the nut is a 15mm. i used a craftsman wrench and even though both the craftsman and gearwrench were supposedly the same size, they were not. if you use the open end of the wrench you can get it on the nut inside the frame by inserting it in the opening near the lower control arm. then with another 15mm you can trun the bolt out. since i replaced my front bumper, i replaced the broken nuts with 2 that held on my original skid plate. its a great way to make use of old parts and also these have no nut the break off therefore eliminating the chance of having this happen again

hopefully the pictures below will help someone out

hopefully the pictures below will help someone out

Last edited: