BoostinChick

Member

Was not a huge fan of the Di-Noc (vinyl) and hydrodipping was expensive and I did not like any of the patterns I saw at various shops - it looked too fake to me. I looked into carbon fiber skinning and materials were actually cheap! The drawback is that it is time-consuming. I started with the climate control panel and the piece directly underneath that has the Microsoft SYNC badge. Don't worry! This trim piece had deep scratches along the top and some minor damage. It was a good sacrificial piece. I had to fill it in and sand smooth...

I chose a honeycomb pattern to be different. Everyone has or does the 2x2 twill.

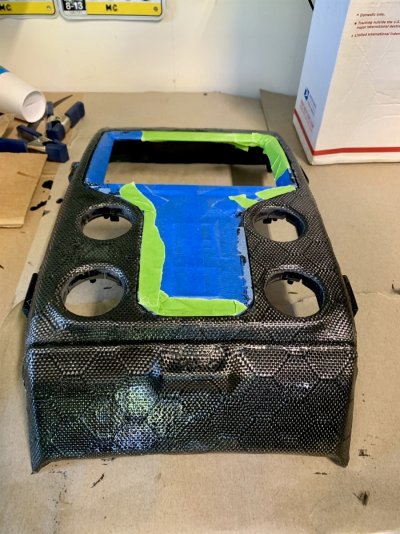

This was after the first resin coat dried and I was able to trim any excess and cut out the sections I needed to.

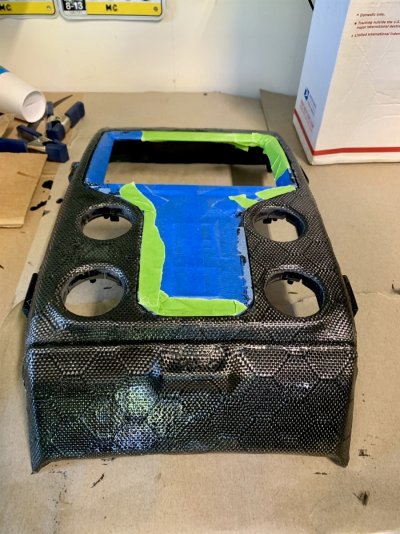

3rd coat that's drying now. Tried to show the 3D effect this has which is pretty cool. For my first project and working with real carbon fiber, it turned out OK. I still need to wet sand and polish to get things even.

I chose a honeycomb pattern to be different. Everyone has or does the 2x2 twill.

This was after the first resin coat dried and I was able to trim any excess and cut out the sections I needed to.

3rd coat that's drying now. Tried to show the 3D effect this has which is pretty cool. For my first project and working with real carbon fiber, it turned out OK. I still need to wet sand and polish to get things even.