So after putting this off forever, I finally sucked it up and tackled it. I will say I don't think this is really a job for your standard shadetree mechanic. I did have to buy a new digital torque wrench with torque as well as angle. It was a real blind knuckle buster of a job that needed lots of extensions, swivels, and multiple drive sizes per socket. It took me 12 ish hours, but thats an estimate as I did it over the course of a week and I also cleaned the air filter and changed the front diff fluid.

SO here is the start, getting my tools and parts laid out. The job actually has to be done on the ground because you can have the axles droop.

Started by draining the oil and removing the filter

The stock POS plastic oil pan covered in leaky oil and dirt. This made for a VERY messy/oily job.

Next you have to remove the front axle bolts and lower the front axles as much as possible to get to the oil pan bolts. The plastic oil pan comes out first.

Here it is with quite a bit of sealant on it from its second dealer replacement (this job is putting a FOURTH oil pan in this truck, if you want something done right, you gotta do it yourself)

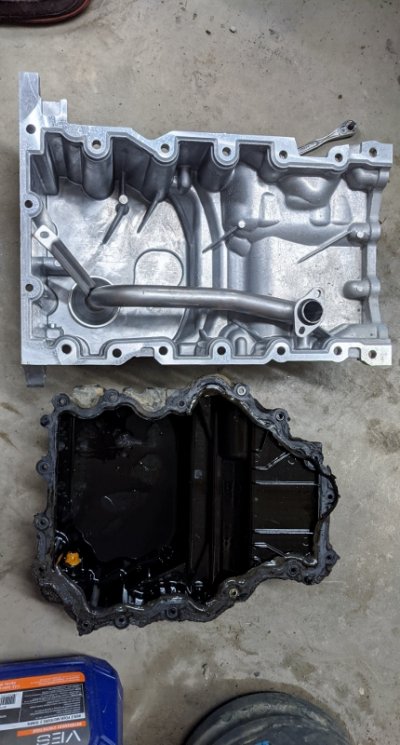

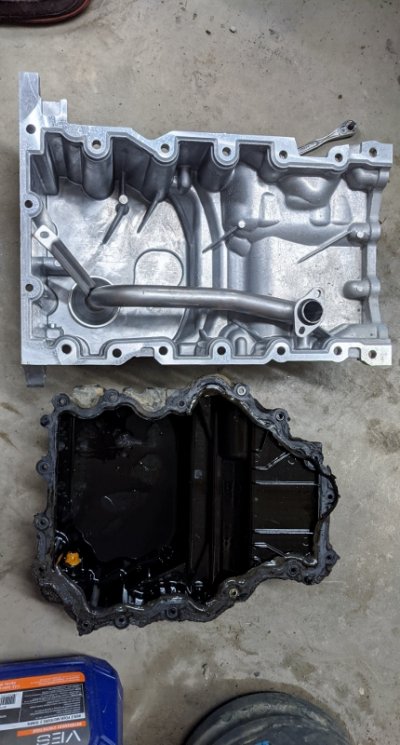

Here is the plastic pan vs the new metal pan (as well as the new oil pickup) the visual difference is because the block stiffener hasn't been removed yet.

Now here is the plastic pan with the old stiffener

Here is the underside of the motor with the pan, stiffener, and oil pickup removed. The sealing surfaces need to be cleaned of all old sealant and oil.

Here are the surfaces all shined up. It is ridiculous how many sealing surfaces there are for this thing with angles and seams.... Seems like a bad design to me, but what do I know.

I numbered the torque pattern as this part is critical. Once you get the sealant on, you have 1 minute to wiggle the pan up into a spot where it barely fits, without wiping off your sealant bead, then you have 4 minutes to get the corner bolts hand tight, then you have 1 hour to get the pattern with 177 in/lbs followed up by 45 degrees, then torque the 3 bellhousing bolts, then the 4 front bolts. Of courser about half the bolts are difficult to get to.

Then here it is all bolted in!

All you have to do now is reinstall the intake piping, the front axles, the skid plates, fill it with oil and cross your fingers.

SO here is the start, getting my tools and parts laid out. The job actually has to be done on the ground because you can have the axles droop.

Started by draining the oil and removing the filter

The stock POS plastic oil pan covered in leaky oil and dirt. This made for a VERY messy/oily job.

Next you have to remove the front axle bolts and lower the front axles as much as possible to get to the oil pan bolts. The plastic oil pan comes out first.

Here it is with quite a bit of sealant on it from its second dealer replacement (this job is putting a FOURTH oil pan in this truck, if you want something done right, you gotta do it yourself)

Here is the plastic pan vs the new metal pan (as well as the new oil pickup) the visual difference is because the block stiffener hasn't been removed yet.

Now here is the plastic pan with the old stiffener

Here is the underside of the motor with the pan, stiffener, and oil pickup removed. The sealing surfaces need to be cleaned of all old sealant and oil.

Here are the surfaces all shined up. It is ridiculous how many sealing surfaces there are for this thing with angles and seams.... Seems like a bad design to me, but what do I know.

I numbered the torque pattern as this part is critical. Once you get the sealant on, you have 1 minute to wiggle the pan up into a spot where it barely fits, without wiping off your sealant bead, then you have 4 minutes to get the corner bolts hand tight, then you have 1 hour to get the pattern with 177 in/lbs followed up by 45 degrees, then torque the 3 bellhousing bolts, then the 4 front bolts. Of courser about half the bolts are difficult to get to.

Then here it is all bolted in!

All you have to do now is reinstall the intake piping, the front axles, the skid plates, fill it with oil and cross your fingers.