More progress, cylinder torque plates! Got them roughed in, these will get bored oversized to clear any bore combo and both sides resurfaced flat. From there, spacers are made to fit the head studs.

Using torque plates or deck plates as some call them, is the only way to ensure cylinders are straight and round when the cylinder heads are torqued up for final assembly. Bores are distorted from fastener torque and will become egg shaped if honed without simulating the heads being installed. Same principle with main bores being torqued up, however that’s not as critical in an iron block application.

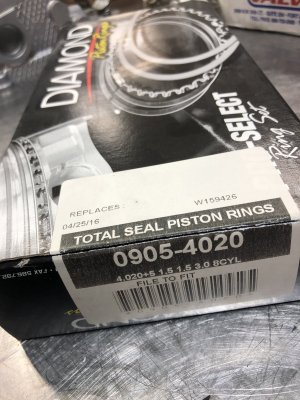

Torque plates have been proven to increase ring seal and adds life to your rings and pistons. This translates directly to horsepower, as the rings have less blow by and keep cylinder pressures where they belong, in the cylinder, not your crankcase!