Video too big. I’ll find another way. But this is what I wrote before figuring that out…

I went back and read my post, ‘phasers - from the top’ so as not to re-cover much that is there. In that post there was some material on what is different about the updated cam phasers. But there was an important difference that I neglected, and I have come to the conclusion that it is critical.

Let’s first note some of the cam phasers update sequence in part numbers. When the raptor ecoboost truck was released, the cam part numbers were prefixed with the letters HL3Z and suffixed with a 2 letter revision number such as CB, CC, and finally CD as the last one. Then subsequently, a new part was released by a new manufacturer and this part was prefixed with the letters ML3Z and suffixed with the letter ‘A’. I know the differences between cc, cd, the ml3z-a parts, but not earlier HL3Z parts. Interestingly, when HL3Z-***-CD came out, ML3Z-***-A was flagged as an alternate. Then, in a subsequent bulletin, CD was flagged as the alternate and ML3Z as the primary.

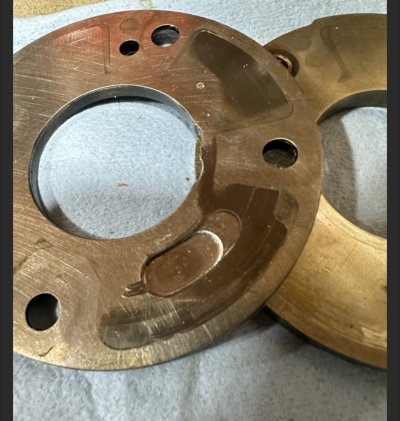

Now the differences. Recall from the ‘from the top post’, a patent was noted. The “prior art” discussed in that patent is the ford design (and many others). The oil pressure which pushes the locking pin out to the unlocked position, is the same oil pressure that retards the exhaust or advances the intake. This means there is a shear force tangential to the unlock motion, and this is a source of wear on the lock pin well. Over time, the exiting pin will ream out the rim of the well on one side. You can find lots of pictures of this from just about any manufacturer from Toyota to Bugatti. And if this happens at 150k miles or greater, no one will be surprised, just grumbling. But ford has had a problem at very low mileages in some cases. In the attached video, you can see that on the CD part there is a modification to the pin well from the CC part to the CD part. This will have been done to improve the prior art aspect of the problem. The well in the CC part (not shown) had a partial well. Meaning the well side wall on about 25% of the well was not present. This is where oil flowed in. In the CD part, this was remedied. The side wall exists, and oil is allowed to enter at the bottom of the well. Assuming ford thought shear force was the issue, this was a big step towards fixing it. The ML3Z part also has this robustness. Different, but not materially so.

The ML3Z part however has another distinct difference. As noted in the other post, the lock pin is pushed into the well by a spring when the pin is over the well hole and oil pressure is cut. The spring is pretty close to what you would find in any old ballpoint pen. Fragile and much smaller in diameter than the pin itself. The non-pin side of the spring is centered by a plastic component. Here is the big difference. In the HL3Z parts, that piece of plastic slides on the back plate as the rotor moves. It’s lubricated by the phaser oil pressure but it is subject to wear. It is important that oil be able to seep past it. In the ML3Z part, this plastic piece is altogether different. It press fit into the rotor and does not contact the back plate. It is not subject to any sliding wear, ever.

I originally dismissed this difference. Then I talked to a guy on the forum who described looking at his disassembled HL3Z-***-CC part and said the plastic piece had disintegrated. If that piece is not there, the spring has nothing to center it. At a minimum the spring wears and fast because the surface contact is so small. It could also just fold up. Without sufficient spring pressure, the pin might not seat, or may jam. Who knows. A rattling phaser with minimal well rim wear is surely this problem. That is what the guy on the forum showed. Not a lot of rim wear.

The question is, which wear happens first; the patent shear wear or pin disintegration. My thinking has evolved to this: the pin well wear is a 150k mile failure. The plastic is a 10k to 50k mile hazard. My thinking is indeed that the ML3Z part knocks both problems on the head. The CD part hits one of them…

See the video for some detail on this…

Now, perhaps this is not what you were after or care about. When I bought my truck I wanted to know if I had the latest phaser parts and the 21b03 software. I checked ford’s fordpass app. There was no mention in there. But there were records and where the work was performed. I called the service centers one by one and gave them the vin and dates. Sure enough, I found a ford service center that had done the phaser update and software. It was under warranty at the time and they apparently don’t log that sort of thing in anything fordpass has access to. They sent me the service records and it shows I have the CD part. There is about 50k miles on them. I hear there is a ford database called oasis, which any ford service center has access to. That should show such work. I’ve never looked but I would recommend you try.