full-race geoff

Full Access Member

We took the two big turbo trucks out and had some fun

killed the tires on the grey truck (Not sure what rubber to try next)

Meanwhile my team and I are finalizing some Gen3 and bronco / ranger projects, trying to wrap before the end of year. I’m grabbing a few hours here and there for my project.

A potential win for my Gen 3/2/1 setup is I test fitted the Gen2 AC compressor and it fits the Gen 3 block and Harmonic balancer (as well as a Gen 1 block). they all share the same bolt pattern and appear to be cross compatible. The dowels looks slightly different only. If Gen 2 ac compressor/lines does in fact fit up to a Gen 3 3.5L longblock … the remaining wildcard is knock sensor. Although that’s a big one that I may not be able to answer without hands on testing with an expert calibrator. Still

More to figure out.

a couple weeks ago I test fitted the gen2 4.88 front diff and steering rack in my gen 3 Frankenframe and it all fit perfectly. Lots of room for diff cover activities. <Spicer Dana 8.8 diff covers are on long backorder until April or May fyi>. Not sure if I’m going to weld the diff case mounts right now although I made some cardboard templates at lunch yesterday. Have so much other things to focus on currently it’s the least of my worries.

I decided to try and get my Gen 2 hubs and knuckles to fit the Gen 3 frame. This would keep the hubs/bearings/lca/knuckle changes to a minimum and get me rolling quickly however it also might be a fail I don’t know yet. FYI a Gen 3 knuckle is 0.700” taller than a Gen 2 knuckle. So I’m going to make a taller steering knuckle misalignment using Camburg UCAs and machining taller misalignment spacers.

For fun I tried 3D scanning with my iPhone. Did not work out well so back to cad, drew it up 0.700 taller and also made another variant at 0.750 and 3D printed a pair before running on the lathe. After the holiday I will cycle the susp to check bumpsteer then decide if I’m wasting time here. I don’t really want long travel and definitely don’t want dual shocks up front - They block critical access to engine and turbo

For the record: Some people online say the ball joint taper is 7 degrees - it’s actually 6.4 degrees

In other news, PRI was last week and the three raptor related updates:

Nostrum DI fuel pump debut in their PRI booth: https://www.full-race.com/nostrum-2017-2020-f150-ecoboost-hpfp DI makes more power on gasoline. I ordered one for my truck, will test it on the stock motor first

Engine builder magazine had the SI valves on display (although I’m unsure why they call them gen3 and not gen2/3): https://www.enginelabs.com/news/si-valves-and-headgames-motorworks-team-up-on-gen-3-ecoboost-valves/

GSC is releasing an all new valve spring kit. The owner Greg has a gen 2 raptor and says cams are next.

Meanwhile my team and I are finalizing some Gen3 and bronco / ranger projects, trying to wrap before the end of year. I’m grabbing a few hours here and there for my project.

A potential win for my Gen 3/2/1 setup is I test fitted the Gen2 AC compressor and it fits the Gen 3 block and Harmonic balancer (as well as a Gen 1 block). they all share the same bolt pattern and appear to be cross compatible. The dowels looks slightly different only. If Gen 2 ac compressor/lines does in fact fit up to a Gen 3 3.5L longblock … the remaining wildcard is knock sensor. Although that’s a big one that I may not be able to answer without hands on testing with an expert calibrator. Still

More to figure out.

a couple weeks ago I test fitted the gen2 4.88 front diff and steering rack in my gen 3 Frankenframe and it all fit perfectly. Lots of room for diff cover activities. <Spicer Dana 8.8 diff covers are on long backorder until April or May fyi>. Not sure if I’m going to weld the diff case mounts right now although I made some cardboard templates at lunch yesterday. Have so much other things to focus on currently it’s the least of my worries.

I decided to try and get my Gen 2 hubs and knuckles to fit the Gen 3 frame. This would keep the hubs/bearings/lca/knuckle changes to a minimum and get me rolling quickly however it also might be a fail I don’t know yet. FYI a Gen 3 knuckle is 0.700” taller than a Gen 2 knuckle. So I’m going to make a taller steering knuckle misalignment using Camburg UCAs and machining taller misalignment spacers.

For fun I tried 3D scanning with my iPhone. Did not work out well so back to cad, drew it up 0.700 taller and also made another variant at 0.750 and 3D printed a pair before running on the lathe. After the holiday I will cycle the susp to check bumpsteer then decide if I’m wasting time here. I don’t really want long travel and definitely don’t want dual shocks up front - They block critical access to engine and turbo

For the record: Some people online say the ball joint taper is 7 degrees - it’s actually 6.4 degrees

In other news, PRI was last week and the three raptor related updates:

Nostrum DI fuel pump debut in their PRI booth: https://www.full-race.com/nostrum-2017-2020-f150-ecoboost-hpfp DI makes more power on gasoline. I ordered one for my truck, will test it on the stock motor first

Engine builder magazine had the SI valves on display (although I’m unsure why they call them gen3 and not gen2/3): https://www.enginelabs.com/news/si-valves-and-headgames-motorworks-team-up-on-gen-3-ecoboost-valves/

GSC is releasing an all new valve spring kit. The owner Greg has a gen 2 raptor and says cams are next.

Last edited:

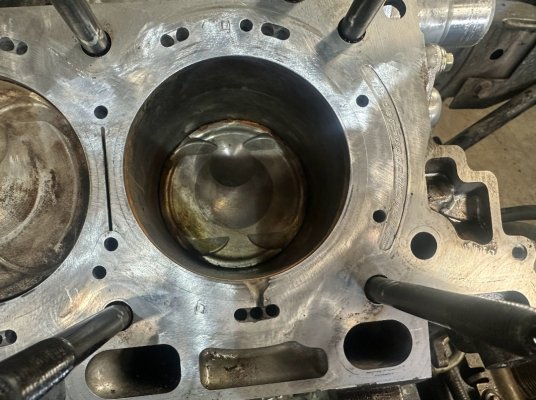

It is a high milage engine and trans that was neglected before me so I can't expect everything to be perfect.

It is a high milage engine and trans that was neglected before me so I can't expect everything to be perfect.