Any updates?You can see the difference and i will try and for few days and let you know guys

View attachment 385305

EVAP Check Engine

- Thread starter TBone22

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Alhasawi

Member

- Joined

- Nov 7, 2017

- Posts

- 23

- Reaction score

- 10

I still got the check engine light back on with the same codeAny updates?

Could you tell me if u have turbo adapters aswell as the turbo inlet pupes?

Most of my friends here have installed the turbo inlet pipes with no issues but the only difference is i have the turbo adapters as well the inlet

I think it caused a lot of pressure thats just a theory and an idea top of my head

Cos nearly all ppl who installed the turbo inlet pipes have no issues

I don't have turbo adapters yet, but am considering it when I install the downpipes. After communicating with a tech from AEM they reported that it's a sensor that is just out of range, but the people that had this problem bought the AFE version that comes with two different hoses have not had this problem return. I'm going to order them tomorrow, you have to call and place the order over the phone because they don't list them on their site. I found the part numbers on their instruction manual and sent them an email and they asked me to call and place the order. They are not expensive at all so I'm going to give it a shot.I still got the check engine light back on with the same code

Could you tell me if u have turbo adapters aswell as the turbo inlet pupes?

Most of my friends here have installed the turbo inlet pipes with no issues but the only difference is i have the turbo adapters as well the inlet

I think it caused a lot of pressure thats just a theory and an idea top of my head

Cos nearly all ppl who installed the turbo inlet pipes have no issues

I also found a newer thread on a different forum that says it's an EGR vacuum control that throws the code, but I'm not sure exactly how this issue causes that sensor to go out of range. I tried running the diagnostic routine for the specific code, but I need a licensed FORD PCM handheld to turn on and off stuff during the diagnostic process while monitoring fuel tank pressure voltage. I really don't feel like dropping 500+ dollars for the hardware and license. https://www.ranger5g.com/forum/threads/p04f0-code-evap-system-problem.23985/

AFE 951-493-5608

05-01577 =$32.55

05-01585 = $35.84

Plus Shipping

Alhasawi

Member

- Joined

- Nov 7, 2017

- Posts

- 23

- Reaction score

- 10

I already tried both

I am back to stuck now both sides to see if the engine light will come back on

I am back to stuck now both sides to see if the engine light will come back on

Alhasawi

Member

- Joined

- Nov 7, 2017

- Posts

- 23

- Reaction score

- 10

More than a week now with stuck inlet pipes also i am pushing the car for a bit to create a high pressure but i did not get a check engine light so what i think is its a inlet pipe problem and my car can not adjust to the new high pressure caused by the inlet

New recaros

FRF Addict

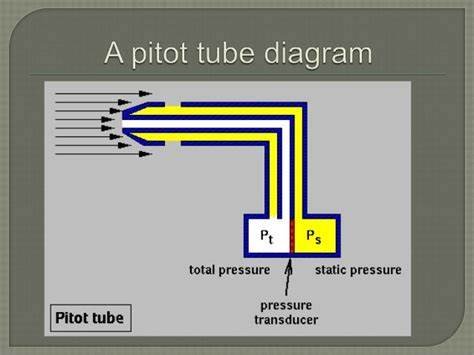

Guys, the second picture on page one of this thread under new design looks like a Peto tube. It measures a differential pressure and that measurement gets converted to a flow measurement.

I will suggest that it’s a flow measurement issue, not a pressure issue. If the pipes are larger in diameter, the velocity will be less for the same flow. Less velocity on a Peto tube would result in a lower differential. The computer see that as low flow. The computer/sensor is not calibrated for the larger pipes, so it shows a low flow when it’s really not. The solution if this is the case is, recalibrate the computer for the larger pipes.

Also, just for reference, a Peto tube should be in the center of the pipe and have at least 3 pipe diameters of straight pipe in front of it. That accuracy probably not needed here. AFE should have realized this error.

I can’t tell by the pictures, but is it possible that the tube is 180 off?

I will suggest that it’s a flow measurement issue, not a pressure issue. If the pipes are larger in diameter, the velocity will be less for the same flow. Less velocity on a Peto tube would result in a lower differential. The computer see that as low flow. The computer/sensor is not calibrated for the larger pipes, so it shows a low flow when it’s really not. The solution if this is the case is, recalibrate the computer for the larger pipes.

Also, just for reference, a Peto tube should be in the center of the pipe and have at least 3 pipe diameters of straight pipe in front of it. That accuracy probably not needed here. AFE should have realized this error.

I can’t tell by the pictures, but is it possible that the tube is 180 off?

Last edited:

New recaros

FRF Addict

Any ideas on where this calibration would be in the PCM? I installed the tube that you mention earlier along in this thread and over time the issue came back. The instructions say to face the slanted opening portion towards the turbo, but wouldn't it make sense to face it away from the turbo so it's picks up the incoming air?Guys, the second picture on page one of this thread under new design looks like a Peto tube. It measures a differential pressure and that measurement gets converted to a flow measurement.

I will suggest that it’s a flow measurement issue, not a pressure issue. If the pipes are larger in diameter, the velocity will be less for the same flow. Less velocity on a Peto tube would result in a lower differential. The computer see that as low flow. The computer/sensor is not calibrated for the larger pipes, so it shows a low flow when it’s really not. The solution if this is the case is, recalibrate the computer for the larger pipes.

Also, just for reference, a Peto tube should be in the center of the pipe and have at least 3 pipe diameters of straight pipe in front of it. That accuracy probably not needed here. AFE should have realized this error.

I can’t tell by the pictures, but is it possible that the tube is 180 off?

New recaros

FRF Addict

I would install it the direction Ford has it. I have never saw one installed pointing in the direction of flow. Not sure that would ever work. Hmm. I have no idea about programming a vehicle. Goose or FTO question. Even then you would have to have all the coefficients which only AFE would have. Maybe, they screwed up the install directions and a calibration is not needed. I would question AFE hard about the direction, surely they have engineers that could help. Explain the tube and ask about the proper direction.

Similar threads

- Replies

- 4

- Views

- 628

- Replies

- 2

- Views

- 273

- Replies

- 12

- Views

- 2K

- Replies

- 56

- Views

- 8K

Staff online

-

Big BlueAdministrator

Members online

- Keamg5

- Coguy

- username95510

- julien194b

- Dalejbrass

- kcbrockett

- spring

- nikhsub1

- HTXaggie

- hh60afets

- JDMCTR00

- elusion23

- srchrist

- GCATX

- R3P7ER

- BP31

- hingedthinker

- mprice1234

- Zeusmotorworks

- Stingray23

- relak

- cody919

- jpavmirk

- HulkSmash23

- NickyF25

- SDB666

- additionalband

- md270raptor

- taquitos

- MotorsportsAustin

- Big Blue

- EastEndAngler

- icecoldak

- North796

- New recaros

- DaveInMn

- roadwarrior318

- Goose8651

- Pikser

- Bozz

- MurderedOutSVT

- Tireworld

- thatJeepguy

- sixshooter_45

- IMFletcher

- RoBear

- JohnnyOxGen3

- StuartR

- GEN3LV

- TENbarrel85

Total: 1,827 (members: 64, guests: 1,763)