Rotora's rotor is only 1mm thicker than stock, the overall thermal mass isn't really increased at all, pretty sure Alcon is in the same boat. Compound Mu is generally pretty tame for most street pad compounds too, so you're not dumping a ton of heat into the rotor unless your dragging the brakes down the side of a mountain.

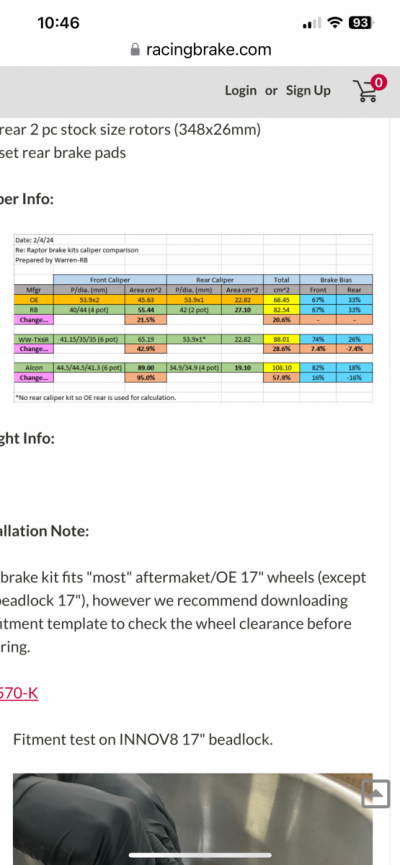

A larger area pad will operate at a cooler temperature and live a longer life than a smaller area pad. The most important factor of the caliper is piston area, and the main benefit in moving to a fixed caliper is increasing rigidity and reducing deflection in the system which makes for a more efficient braking system. All of this has been proven time and time again in the racing world.

I've designed a multitude of brake kits, I have no qualms with the approach I'm taking. Bigger rotor would be nice but that's not in the cards to fit behind a stock wheel (and it jacks up consumable cost a good bit). Any of the kits on the market (and the one I'm designing) would be plenty for 99.9% of people, it's just that none of the kits on the market check all of my boxes.

It also depends on the size of the air-gap in the center. Competition rotors for racing cars often have thinner braking surfaces and a larger air-gap for cooling and less unsprung weight, but as a result, cannot "store" as much heat (and use up really expensive brake pads like they're free

I have no idea what the weight difference is between the aftermarket and factory rotors of the same size, that would be interesting to find out.