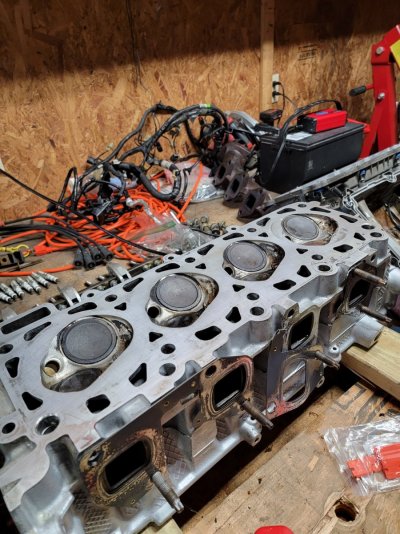

A while ago I had the dreaded broken valve spring and unfortunately for me dropped the valve and caused some wicked engine damage. Long story short I sent my motor to a company to be remanufactured who deemed my head and block acceptable to do so. Once it was back and reinstalled the head gasket was leaking coolant mainly into the same cylinder I had issues from. Melted the heat tab on that side so engine company has of course refused to be any help even though I never allowed the truck to overheat. Essentially I am trying to figure out the cause of the head gasket failure and go from there. I only have a couple theories -

1. The scoring from the damage is creating little avenues where the cylinder pressure is wanting to force itself

2. The company used some type of red spray adhesive on the surfaces. This possibly caused failure since the service manual and felpro both state not to do so with the MLS gasket

3. Faulty gasket/Procedure?

I've checked flatness with a straightedge and confirmed the head is still perfectly flat. Is it possible to maintain a good head gasket seal with the knicks present? None of them are outside of the "ring" area of the gasket. I know the safest option would likely be to purchase a new head but that is my last resort.

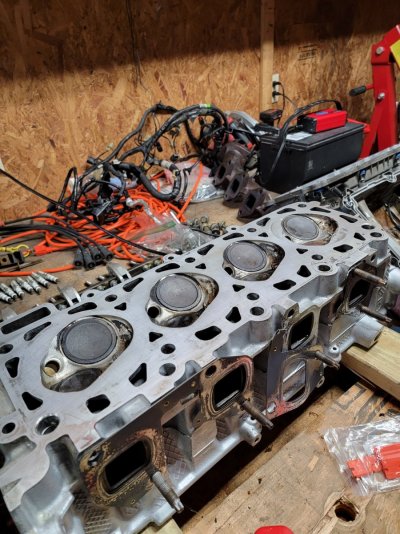

1. The scoring from the damage is creating little avenues where the cylinder pressure is wanting to force itself

2. The company used some type of red spray adhesive on the surfaces. This possibly caused failure since the service manual and felpro both state not to do so with the MLS gasket

3. Faulty gasket/Procedure?

I've checked flatness with a straightedge and confirmed the head is still perfectly flat. Is it possible to maintain a good head gasket seal with the knicks present? None of them are outside of the "ring" area of the gasket. I know the safest option would likely be to purchase a new head but that is my last resort.