Outlaw Offroad

Full Access Member

- Joined

- Apr 7, 2011

- Posts

- 624

- Reaction score

- 311

The Truth About Raptor Bump Stop Kits:

Before you run out and spend your hard earned cash, it’s important to first understand what and why a correctly designed bump stop kit is necessary for some but not all.

Our first and foremost goal is to educate the Ford Raptor owner on the inherit problem and identify the correct product designed to prevent your Raptor from bending the rear frame. In NO way are we trying to say negative things about other company’s products. However, there is proper procedures in designing & testing of the bump stop kit and other Raptor products. We have spent the last several months testing several different designs of rear bump stop kits on/off road. We have put these kits to the test. Some of our designs “were” very similar to ones you see being offered to you online today. If you pay close attention to our design, you will see it is very different to any other on the market.* So why is that?

Outlaw Raptor History:

Outlaw Raptor was first established based around our Off Road Expedition’s and Tours. Our goal was to sell & install products that were already currently manufactured by other companies (as we do with our sister company Outlaw Offroad) but soon realized by using the truck off road that most of the products on the market were just not up to the standards of what is needed to be used off road. A lot of the products were produced for financial gain with little thought or design to actually improve performance and durability. It was then when we decided to embrace the Ford Raptor and bring to the market products that were truly designed and tested for use off road. Unfortunately in the competitive aftermarket parts off road industry, there are far too many manufactures that manufacture parts but do not take the last steps to properly test the finished products to ensure proper functionality.* I am sure most everyone knows of or has heard of the “Monster Energy Outlaw Raptor Expeditions Run” we put on every month which requires your Ford Raptor being able to work in at times very harsh and grueling environments. These runs are the true testing grounds on man, machine and product. As we have said before, products that Outlaw Raptor manufactures and designs are not for every Ford Raptor owner. Our products are designed for Raptor enthusiasts who truly want to use their Ford Raptor off road knowing they can put their mind at ease knowing your parts were tested and proven.

The Problem about other Bump Stop kits:

Let’s get down to the nitty gritty of the problem which causes the frame of the Ford Raptor to mushroom inward at the OE bump stop area. The bowing or arch downward of the frame is caused by the upward full compression of the rear axle hitting the OE bump stop which is located in the frame rail. Some have claimed that it is a design flaw by Ford and others have said the truck is being used off road in an abusive manor. Whichever you believe causes the problem, one thing we all agree on is to prevent the problem from happening to your raptor. You need to know and understand the problem. Secondly, you need to understand why some products will work better than others.*

What other manufactures of aftermarket bump stop kits are failing by to mention in their video footage that looks cool on a computer screen is that your Ford Raptor doesn’t need a rear bump stop kit on 12”-16” flat whoop sections. Your Ford Raptor can go over 12” to 16” whoops just fine without any type of aftermarket bump stop kit. You can “youtube” Raptors going over 24” whoops with NO problems. The Raptor come’s stock with 35” tall tires and eats up most anything you can throw at it. The difference between the design, engineering and especially the off road testing allows us to really bring the problem to light. This is where the knowledge and understanding of the Ford Raptor and how it behaves off road by testing both the truck and aftermarket products play a big part in correct product design.

The Cause of the Problem:

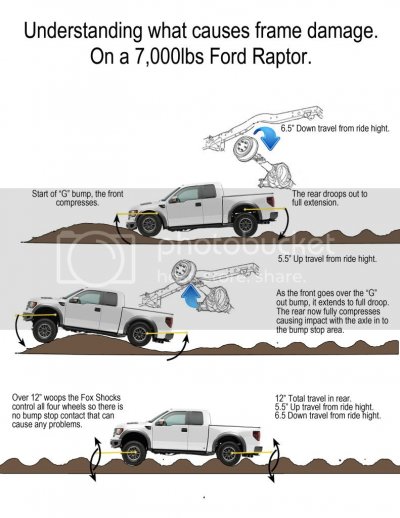

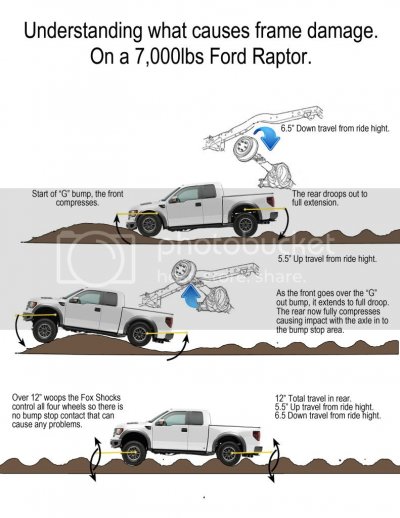

The Ford Raptor with stock rear spring has 5.5” of up travel and 6.5” of down travel from where the truck sits level on the ground. It has an OE rubber built in bump stop that works. But what caused the frame issue is the compression of a “G” out due to the long wheel base and limited travel of the truck. When a Raptor goes over whoops all four wheels are independently moving and being controlled by the Fox shocks. When a “G” out occurs it is when the front is working on an opposing direction the rear. The front suspension will first contact the “G” out dip causing the front suspension to compress and the rear to extend to full droop the after most frame bending “G” outs their is a bump or mound witch the front of the raptor will now fully extend or droop out this causing the rear now to fully compress in the the “G” out hole then hit the bump or mound and it is this what caused the frame mushrooming affect or bending of the frame. (See diagram below)

So what works and what does not?

There is a good reason why the engineers at Ford and SVT designed the frame with structural contours and did not just box the frame rails. One of our first designs was just to plate and box it in just like the some from some other manufactures. This ended in extreme failure and right back to the design phase. After working with a structural engineer, a well known trophy truck fabricator and after several discussions about structural design with an engineer at SVT who all had a very important input on the design of our bump stop and frame gusset kit. We fully boxed & encapsulated the frame rail (utilizing the factory OE frame curvature on both the back and front side of the frame rail) and joined both the driver and passenger frame supports together with a heimed chromoly 120 walled cross support. By doing frame supports this way, we were able to preload the encapsulated frame supports to maintain the correct geometry rather than using a flat plate that misses all OE supporting contours of the factory frame rail like other kits do. The facts lie in the proper engineering, design, and off road testing behind our Frame Support Kit for maximum durability and support.

Outlaw Raptor Rear Bolt on Bump Stop and Frame Gusset Kit - YouTube

If you watch the video at 1 min 24 sec the bump stop goes to full bump and if you watch the bump stop bracket nothing moves at all. By having the bump stop bracket fully encapsulated the frame rail on inside as well as the out side all the stress is taken off the factory bump area.

We have seen and dealt with many failures on other manufacture’s products on the Raptor runs. All related to other manufactures products poorly designed products. We don’t want to see you buying the wrong product the first time due to manufactures lack of testing and development. Outlaw Raptor has sold over 53 bump stop frame gusset kits in the last 2 months and have another 12 more set’s shipping this week. Outlaw Raptor is working on other known Raptor issues and will be coming up with tested fixes for those. I assure you that before you get to bolt on one of our products, it has been personally tested by me and my engineers.

If you have question please e mail [email protected]

Or call the shop 949-581-5001

Before you run out and spend your hard earned cash, it’s important to first understand what and why a correctly designed bump stop kit is necessary for some but not all.

Our first and foremost goal is to educate the Ford Raptor owner on the inherit problem and identify the correct product designed to prevent your Raptor from bending the rear frame. In NO way are we trying to say negative things about other company’s products. However, there is proper procedures in designing & testing of the bump stop kit and other Raptor products. We have spent the last several months testing several different designs of rear bump stop kits on/off road. We have put these kits to the test. Some of our designs “were” very similar to ones you see being offered to you online today. If you pay close attention to our design, you will see it is very different to any other on the market.* So why is that?

Outlaw Raptor History:

Outlaw Raptor was first established based around our Off Road Expedition’s and Tours. Our goal was to sell & install products that were already currently manufactured by other companies (as we do with our sister company Outlaw Offroad) but soon realized by using the truck off road that most of the products on the market were just not up to the standards of what is needed to be used off road. A lot of the products were produced for financial gain with little thought or design to actually improve performance and durability. It was then when we decided to embrace the Ford Raptor and bring to the market products that were truly designed and tested for use off road. Unfortunately in the competitive aftermarket parts off road industry, there are far too many manufactures that manufacture parts but do not take the last steps to properly test the finished products to ensure proper functionality.* I am sure most everyone knows of or has heard of the “Monster Energy Outlaw Raptor Expeditions Run” we put on every month which requires your Ford Raptor being able to work in at times very harsh and grueling environments. These runs are the true testing grounds on man, machine and product. As we have said before, products that Outlaw Raptor manufactures and designs are not for every Ford Raptor owner. Our products are designed for Raptor enthusiasts who truly want to use their Ford Raptor off road knowing they can put their mind at ease knowing your parts were tested and proven.

The Problem about other Bump Stop kits:

Let’s get down to the nitty gritty of the problem which causes the frame of the Ford Raptor to mushroom inward at the OE bump stop area. The bowing or arch downward of the frame is caused by the upward full compression of the rear axle hitting the OE bump stop which is located in the frame rail. Some have claimed that it is a design flaw by Ford and others have said the truck is being used off road in an abusive manor. Whichever you believe causes the problem, one thing we all agree on is to prevent the problem from happening to your raptor. You need to know and understand the problem. Secondly, you need to understand why some products will work better than others.*

What other manufactures of aftermarket bump stop kits are failing by to mention in their video footage that looks cool on a computer screen is that your Ford Raptor doesn’t need a rear bump stop kit on 12”-16” flat whoop sections. Your Ford Raptor can go over 12” to 16” whoops just fine without any type of aftermarket bump stop kit. You can “youtube” Raptors going over 24” whoops with NO problems. The Raptor come’s stock with 35” tall tires and eats up most anything you can throw at it. The difference between the design, engineering and especially the off road testing allows us to really bring the problem to light. This is where the knowledge and understanding of the Ford Raptor and how it behaves off road by testing both the truck and aftermarket products play a big part in correct product design.

The Cause of the Problem:

The Ford Raptor with stock rear spring has 5.5” of up travel and 6.5” of down travel from where the truck sits level on the ground. It has an OE rubber built in bump stop that works. But what caused the frame issue is the compression of a “G” out due to the long wheel base and limited travel of the truck. When a Raptor goes over whoops all four wheels are independently moving and being controlled by the Fox shocks. When a “G” out occurs it is when the front is working on an opposing direction the rear. The front suspension will first contact the “G” out dip causing the front suspension to compress and the rear to extend to full droop the after most frame bending “G” outs their is a bump or mound witch the front of the raptor will now fully extend or droop out this causing the rear now to fully compress in the the “G” out hole then hit the bump or mound and it is this what caused the frame mushrooming affect or bending of the frame. (See diagram below)

So what works and what does not?

There is a good reason why the engineers at Ford and SVT designed the frame with structural contours and did not just box the frame rails. One of our first designs was just to plate and box it in just like the some from some other manufactures. This ended in extreme failure and right back to the design phase. After working with a structural engineer, a well known trophy truck fabricator and after several discussions about structural design with an engineer at SVT who all had a very important input on the design of our bump stop and frame gusset kit. We fully boxed & encapsulated the frame rail (utilizing the factory OE frame curvature on both the back and front side of the frame rail) and joined both the driver and passenger frame supports together with a heimed chromoly 120 walled cross support. By doing frame supports this way, we were able to preload the encapsulated frame supports to maintain the correct geometry rather than using a flat plate that misses all OE supporting contours of the factory frame rail like other kits do. The facts lie in the proper engineering, design, and off road testing behind our Frame Support Kit for maximum durability and support.

Outlaw Raptor Rear Bolt on Bump Stop and Frame Gusset Kit - YouTube

If you watch the video at 1 min 24 sec the bump stop goes to full bump and if you watch the bump stop bracket nothing moves at all. By having the bump stop bracket fully encapsulated the frame rail on inside as well as the out side all the stress is taken off the factory bump area.

We have seen and dealt with many failures on other manufacture’s products on the Raptor runs. All related to other manufactures products poorly designed products. We don’t want to see you buying the wrong product the first time due to manufactures lack of testing and development. Outlaw Raptor has sold over 53 bump stop frame gusset kits in the last 2 months and have another 12 more set’s shipping this week. Outlaw Raptor is working on other known Raptor issues and will be coming up with tested fixes for those. I assure you that before you get to bolt on one of our products, it has been personally tested by me and my engineers.

If you have question please e mail [email protected]

Or call the shop 949-581-5001

Last edited: