Finally kicked off this project this yesterday.

Disclaimers: Info here is purely to share and document my experience. If it can help anybody, then great. This is my first engine build, so it will be a learning experience for me and I assume zero responsibility for anybody dicking their shit up.

Background: I've come long way in my 14 months of ownership since purchasing my high mileage gen 1, including an engine replacement and transmission replacement (both not on mine). Those interested can follow our journey to this point in my intro thread.

I was fortunate enough to inherit the engine we replaced and, to this point, I've said "only things I've left to do is re-build an engine and transmission." Not really true though as there's lot's of stuff I haven't done. Anyway, this marks the start of the former.

I'll be honest though, I'm admittedly terrible at documenting my work. I'll do my best and try to answer any questions. So let's get into it.

TEARDOWN

To this point engine has been pulled, intake, fuel rail/injectors, plugs, and most accessories have been removed.

Also note, I'm working without an engine stand. That would make things a little easier for sure. We don't exactly know what killed this engine, but we know piston #8 has completely grenaded at this point.

Stripped off the remaining pulley's on the front which were the water pump and crank/harmonic balancer. The balancer gave me the most fits and honestly the only trouble I had on the tear down because I didn't have the right tool. Your standard harmonic balancer puller (the kind with that foot looking plate and screws into the pulley) won't work and all of the jaw pullers I had at this location were the wrong size. Went and rented a "Chrysler" Harmonic Balancer puller from the parts store and it worked like a charm. Literally the only real advice I can include in this first segment as everything else was just turning screws.

Only thing to take off of the rear was the flexplate/flywheel (yes I know it looks like it's on a stand here):

Removed the water pump:

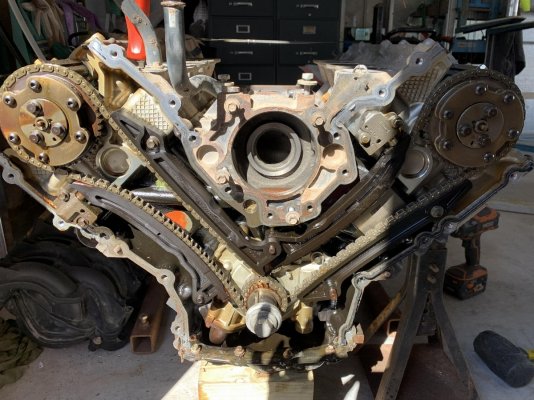

Pulled timing cover:

Pulled off the cam phaser/sprocket and pulled the heads. On bank 2 I pulled the rocker shaft assembly and exhaust manifold, but they could have stayed attached. On bank 1 you will have to deal with the dip stick pipe between the head and exhaust manifold. Couple of ways to skin that cat. Dealers choice though I'd say. Now we get a look at all of the carnage:

Everything else you don't see wound up in the crank case/oil pan. Some noticeable battle scars on the head. I'm thinking it was the rod that failed.

Growing pile of parts

Pulled the oil pan:

Oil Pump:

To expose the bottom end:

And that's where I ran out of time for the day. Would have definitely gotten it all the way apart if I didn't have to fight what that balancer. Live to fight another day.

Disclaimers: Info here is purely to share and document my experience. If it can help anybody, then great. This is my first engine build, so it will be a learning experience for me and I assume zero responsibility for anybody dicking their shit up.

Background: I've come long way in my 14 months of ownership since purchasing my high mileage gen 1, including an engine replacement and transmission replacement (both not on mine). Those interested can follow our journey to this point in my intro thread.

I was fortunate enough to inherit the engine we replaced and, to this point, I've said "only things I've left to do is re-build an engine and transmission." Not really true though as there's lot's of stuff I haven't done. Anyway, this marks the start of the former.

I'll be honest though, I'm admittedly terrible at documenting my work. I'll do my best and try to answer any questions. So let's get into it.

TEARDOWN

To this point engine has been pulled, intake, fuel rail/injectors, plugs, and most accessories have been removed.

Also note, I'm working without an engine stand. That would make things a little easier for sure. We don't exactly know what killed this engine, but we know piston #8 has completely grenaded at this point.

Stripped off the remaining pulley's on the front which were the water pump and crank/harmonic balancer. The balancer gave me the most fits and honestly the only trouble I had on the tear down because I didn't have the right tool. Your standard harmonic balancer puller (the kind with that foot looking plate and screws into the pulley) won't work and all of the jaw pullers I had at this location were the wrong size. Went and rented a "Chrysler" Harmonic Balancer puller from the parts store and it worked like a charm. Literally the only real advice I can include in this first segment as everything else was just turning screws.

Only thing to take off of the rear was the flexplate/flywheel (yes I know it looks like it's on a stand here):

Removed the water pump:

Pulled timing cover:

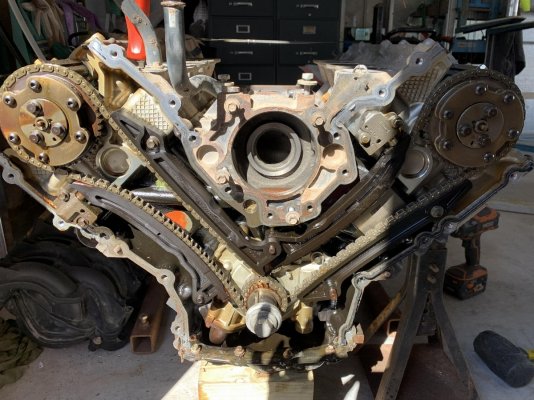

Pulled off the cam phaser/sprocket and pulled the heads. On bank 2 I pulled the rocker shaft assembly and exhaust manifold, but they could have stayed attached. On bank 1 you will have to deal with the dip stick pipe between the head and exhaust manifold. Couple of ways to skin that cat. Dealers choice though I'd say. Now we get a look at all of the carnage:

Everything else you don't see wound up in the crank case/oil pan. Some noticeable battle scars on the head. I'm thinking it was the rod that failed.

Growing pile of parts

Pulled the oil pan:

Oil Pump:

To expose the bottom end:

And that's where I ran out of time for the day. Would have definitely gotten it all the way apart if I didn't have to fight what that balancer. Live to fight another day.

Last edited: