So a few months ago my truck was used in an unnamed tv show (can’t say til it airs) and unfortunately the motor was destroyed. Good news is it was covered, and that’s all I can say about that for now.

I myself actually blew the original motor about a year ago. Some friends and I were in the mountains messing around, I hit some small jumps, enough to dislodge the OEM liner on the drivers side, so when I went through a puddle, water went directly up the intake tube and destroyed the motor. It truely was a perfect storm. So I had the motor replaced, and that second motor was the one destroyed by the show.

That being said, I decided this time to do go all out. I called Livernois. A few months later and a lot of phone calls and emails, my 6.6L 400 cube stroker race motor is finished being built. This is the most powerful Raptor motor they make without a supercharger. Yes some will ask why not a much cheaper LS motor. The main reason is, besides very high end trucks and race vehicles who replace the entire brain, no one really has done it for the average person, and I was not about to be a guinea pig! (Motor specs at bottom)

The motor is going in next week, I am leaving it NA, so we set the compression to 9:5:1 Its being paired with stainless works ceramic coated headers and full 3” exhaust off road pipes, not cats, and 2 magnaflow mufflers. Intake will be an SB intake, BBK throttle body, and a Moroso oil catch can. Also adding Advanced Fiberglass Concepts fenders +2 with liners so I don’t have a repeat of the first motor. As soon as the motor is in it’s getting dyno tuned and properly broken in. As soon as I have pictures of the motor and the install I will update this post as well as the progress and hiccups that I’m sure will happen. As well as the dyno with the HP gains.

I myself actually blew the original motor about a year ago. Some friends and I were in the mountains messing around, I hit some small jumps, enough to dislodge the OEM liner on the drivers side, so when I went through a puddle, water went directly up the intake tube and destroyed the motor. It truely was a perfect storm. So I had the motor replaced, and that second motor was the one destroyed by the show.

That being said, I decided this time to do go all out. I called Livernois. A few months later and a lot of phone calls and emails, my 6.6L 400 cube stroker race motor is finished being built. This is the most powerful Raptor motor they make without a supercharger. Yes some will ask why not a much cheaper LS motor. The main reason is, besides very high end trucks and race vehicles who replace the entire brain, no one really has done it for the average person, and I was not about to be a guinea pig! (Motor specs at bottom)

The motor is going in next week, I am leaving it NA, so we set the compression to 9:5:1 Its being paired with stainless works ceramic coated headers and full 3” exhaust off road pipes, not cats, and 2 magnaflow mufflers. Intake will be an SB intake, BBK throttle body, and a Moroso oil catch can. Also adding Advanced Fiberglass Concepts fenders +2 with liners so I don’t have a repeat of the first motor. As soon as the motor is in it’s getting dyno tuned and properly broken in. As soon as I have pictures of the motor and the install I will update this post as well as the progress and hiccups that I’m sure will happen. As well as the dyno with the HP gains.

- New block bored & stroked to 6.6L 400 cu.in.

- Ceramic coated pistons with thicker ringlands & cross section

- Pro Series billet Rods with ARP 2000 Bolts

- Tri-Armor Coated Main and Rod Bearings

- CNC crankshaft capable of handling 1200hp

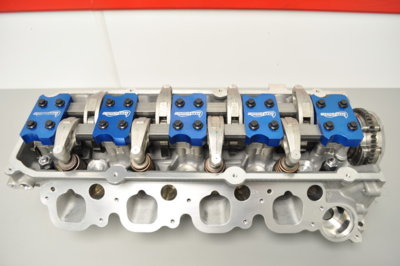

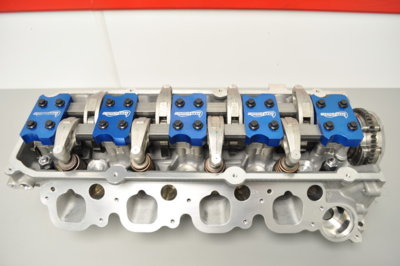

- Fully CNC ported cylinder heads with custom valve job

- Custom camshafts & valve springs

- Variable cam phaser limiters

- Rocker Arm Braces

- Upgraded viton valve seals

- 8740 alloy Main Studs & Head Studs

- Billet oil pump & gears

- EvenFlo 160° low temperature thermostat

- Custom head machining includes:

CNC Probed Block, CNC Machined Block, CNC Decked Block, Hone with Deck plates, Align Honed Mains, Radius Block Oil Passages, Clean Casting Flash, Chamfer Holes, Radius Sharp Edges, Crankshaft Oil Feed Holes Chamfered and Prepped, Crankshaft Polished, Deburr Pistons and Remove Sharp Edges, Hand File Rings