- Joined

- Mar 15, 2013

- Posts

- 3,210

- Reaction score

- 2,342

Plush to waffle weave, glass towels to wash pads, and even more recently polishing pads, microfiber has forever changed how shine freaks keep their cars looking great and how detailers correct, protect, and care for customers cars. The argument could be made that no single advancement in the world of car care has had a larger impact in the last decade than microfiber. Professionals and enthusiasts alike all keep a hefty supply of a wide variety of towels on hand at all times, but despite its omnipresence in the care care world there is still a fair amount of mis-information and mis-understanding as to how they should be cared for.

In this FAQ article I'll be covering the basics of cleaning and care for your microfiber towels and a little bit of background on what makes them the preferred choice of detailers.

WHAT IS MICROFIBER?

WHERE DID MICROFIBER COME FROM?

In this FAQ article I'll be covering the basics of cleaning and care for your microfiber towels and a little bit of background on what makes them the preferred choice of detailers.

WHAT IS MICROFIBER?

What good is it to get into all the minutia of microfiber if you don't first have an understanding of the materials composition and history?

Microfiber can be composed of many parts, most commonly in the detailing / car care industry we use a combination of polyesters and polyamides. These microscopic laboratory born fibers are around 1/100th the diameter of a human hair, this ultra fine thread is what gives microfiber its delicate touch and super soft feel. To put that size into perspective, if you were to think of a regulation basketball as the equivalent of the diameter of a human hair, an individual strand of microfiber would be smaller than an M&M chocolate candy!

Why is this important? While you might see a fluffy towel with your naked eye on a microscopic level there is a very tiny, but very uniform and durable strand there. Almost all microfiber will share an identical fiber structure, regardless of weave or pattern. How the fibers are laid out will impart different characteristics to the material (plush for delicate surfaces, waffle weave for drying, flat for glass, suede for coatings, etc)

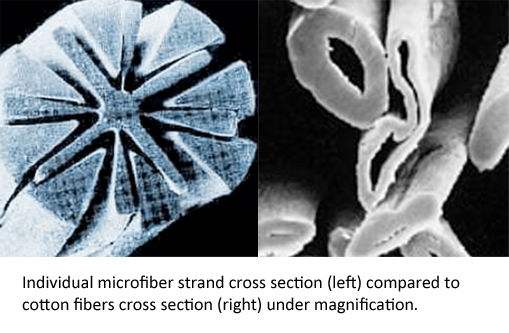

Each individual strand has a star-like structure and all strands are virtually identical across the entire surface of a towel. If you could pull a fiber from one towel, and another from a different towel of similar quality and cross section them you'd likely not be able to tell them apart. This leads to a uniformly soft towel that performs the same regardless of fold or what portion is in contact with the surface. This is in stark contrast to the wild inconsistency of cotton fibers which can vary in shape and size from one strand to the next. (see the image below)

The star shaped structure on each strand allow microfiber to trap small particles, dirt, moisture and debris making them very effective for cleaning. Compared to the inconsistent, tube-like, shape of cotton which is absorbent, but not ideal for cleaning microfiber has a clear advantage.

Microfiber can be composed of many parts, most commonly in the detailing / car care industry we use a combination of polyesters and polyamides. These microscopic laboratory born fibers are around 1/100th the diameter of a human hair, this ultra fine thread is what gives microfiber its delicate touch and super soft feel. To put that size into perspective, if you were to think of a regulation basketball as the equivalent of the diameter of a human hair, an individual strand of microfiber would be smaller than an M&M chocolate candy!

Why is this important? While you might see a fluffy towel with your naked eye on a microscopic level there is a very tiny, but very uniform and durable strand there. Almost all microfiber will share an identical fiber structure, regardless of weave or pattern. How the fibers are laid out will impart different characteristics to the material (plush for delicate surfaces, waffle weave for drying, flat for glass, suede for coatings, etc)

Each individual strand has a star-like structure and all strands are virtually identical across the entire surface of a towel. If you could pull a fiber from one towel, and another from a different towel of similar quality and cross section them you'd likely not be able to tell them apart. This leads to a uniformly soft towel that performs the same regardless of fold or what portion is in contact with the surface. This is in stark contrast to the wild inconsistency of cotton fibers which can vary in shape and size from one strand to the next. (see the image below)

The star shaped structure on each strand allow microfiber to trap small particles, dirt, moisture and debris making them very effective for cleaning. Compared to the inconsistent, tube-like, shape of cotton which is absorbent, but not ideal for cleaning microfiber has a clear advantage.

WHERE DID MICROFIBER COME FROM?

These tiny man made textiles were actually being produced back as early as the 1950's though the applications were extremely limited. Technology at the time limited the had its limitations and it was next to impossible to produce long continuous strands in a consistent manner making it not only very expensive, but also very time consuming to produce. (CLICK HERE TO CONTINUE READING)