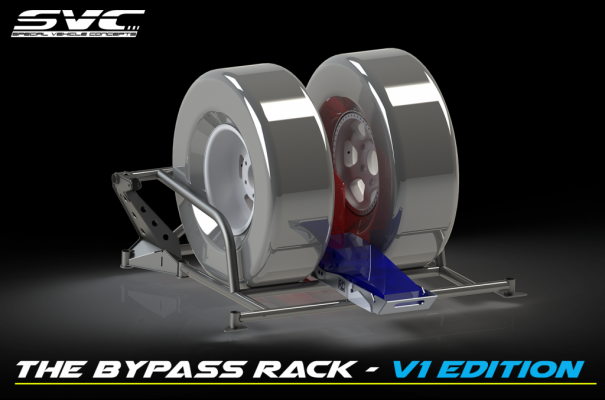

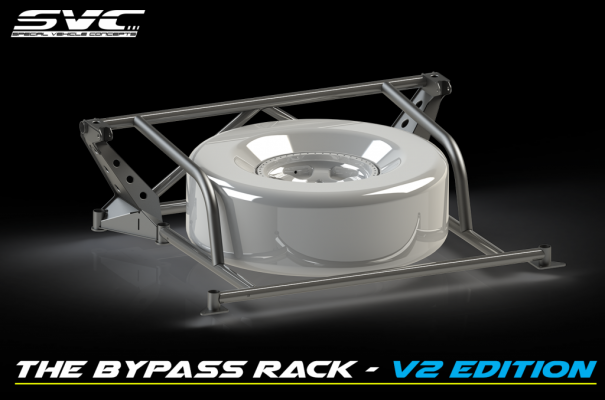

2015 is going to be a very exciting year for SVC. The focus of this year will be upping the ante when it comes to taking our Raptor Suspension systems to the next level. The first phase of this process is our new CAD Designed and CNC laser cut Bypass Rack. Not a week goes by that we aren't building somebody a custom bed cage cargo system that meets the needs for spending long days and even longer miles in the dirt, but with our new Bypass Rack system, you can now have your cargo, and your long travel too.

The system is designed to handle up to a 3.0", 3.5", 4.0" and even a 4.5" if your heart desires. The Bypass Rack will fit Fox or King Bypass shock producing nearly 18" of wheel travel. Our system is designed from the ground up with strength in mind. The forces applied by larger race shock are immense, and the structure holding those shocks needs to be up to the task. To ensure the structure was sound and resistant to twist, we integrated a plate work base system that is designed to add greater strength than other systems on the market. The Bypass Rack shock tower is the actual base structure with internal gusseting for additional support. Because of this, there is a supporting leverage structure to prevent tubes from twisting and breaking welds.

We control the lateral load of the shocks by adding a 1.75" 1.20wall A Frame support structure that adds triangulation to counter act lateral loads wanting to bend and rip the mounts from the truck bed, and a rear facing 1.75" .120 wall tube to prevent the shock mounts from wanting to push towards the front of the truck. What does all this mean? Simple, There isn't a better designed, looking or engineered Bypass shock mounting system on the market.

For more information and pricing, click here Bypass Rack for the V1 and V2 versions. We are now accepting pre-orders.

The system is designed to handle up to a 3.0", 3.5", 4.0" and even a 4.5" if your heart desires. The Bypass Rack will fit Fox or King Bypass shock producing nearly 18" of wheel travel. Our system is designed from the ground up with strength in mind. The forces applied by larger race shock are immense, and the structure holding those shocks needs to be up to the task. To ensure the structure was sound and resistant to twist, we integrated a plate work base system that is designed to add greater strength than other systems on the market. The Bypass Rack shock tower is the actual base structure with internal gusseting for additional support. Because of this, there is a supporting leverage structure to prevent tubes from twisting and breaking welds.

We control the lateral load of the shocks by adding a 1.75" 1.20wall A Frame support structure that adds triangulation to counter act lateral loads wanting to bend and rip the mounts from the truck bed, and a rear facing 1.75" .120 wall tube to prevent the shock mounts from wanting to push towards the front of the truck. What does all this mean? Simple, There isn't a better designed, looking or engineered Bypass shock mounting system on the market.

For more information and pricing, click here Bypass Rack for the V1 and V2 versions. We are now accepting pre-orders.