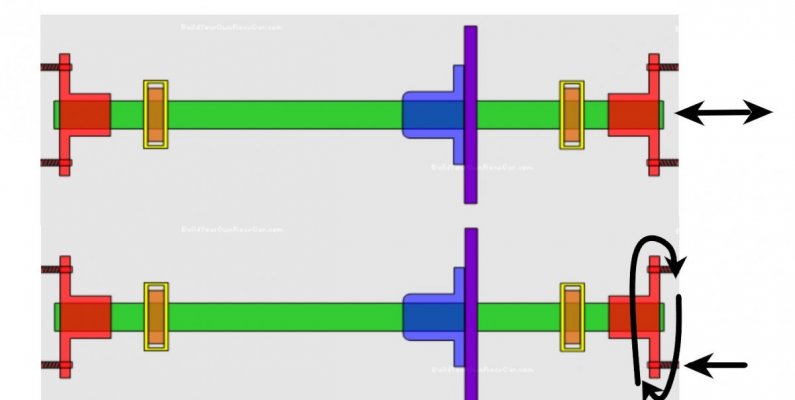

End play is different, it refers to the axle shaft moving in and out, imagine sticking a dial indicator directly in the path of where you would remove the axle, as you push and pull that number will change. Axial play is normally 10x radial on a tapered bearing.

On a 9.75 the axle rotates in an outer bearing, and an inner bearing. And is retained in the carrier with a circlip. There is no provision for removing the play in the circlip and the spider gear tolerances also show in the end play. So when you stack the inner bearing clearance with the circlip clearance you tend to get some play.

Since the bearings do not retain the axle (unlike say a ford 9" where the bearing holds the axle into the carrier) end play has very little to do with bearing clearance. The conical bearings in the unit would have to be completely wasted to affect end play.

Rocking top to bottom implies that outer bearing is smoked, tolerances have opened due to wear or mis-adjustment.

I haven't seen much damage on the outer bearings on these, you do see the pinion bearings get eaten though, especially in blower and big tire applications. When the pinion bearing starts to wear heavily those hardened steel shavings go into the oil and the magnetic plug loads up the shavings are transferred to the entire axle assembly, usually results in a full rebuild. So if you have noises pull the plug and look for metal.