Ok, hahahaha...

@Ruger is just kidding guys, his Gen 1 continues to be trouble free... no excommunication or disintegration necessary.

A point of clarification if you will.

housing was, or was not leaking prior to the t-stat change?

because now I’m suspecting the T stat is not seating, fitting or otherwise orienting properly enough for the o ring seal to work.

I say replace. Although I’ve not had one of these apart in a while <snark> because the Gen2 is ultra reliable, and has no problems </snark> I am familiar with that type of “gasket”. Not that I like them, but I’ve encountered them plus, for extra credit, I’ve actually disassembled and reassembled such an assembly and 1) had no parts left over after reassembly 2) said assembly did not leak after my intervention.

That qualifies me for an internet certified design engineer status.

before checking the housing joint, are we sure it’s not weeping up stream? we should be sure that the hose isn’t weeping, I usually hit a suspect area with something that will show evidence of a leak, so in this case I would coat the housing just below the hose mating with chalk line chalk, baby powder or similar. if it’s leaking upstream of the housing joint, that will show it.

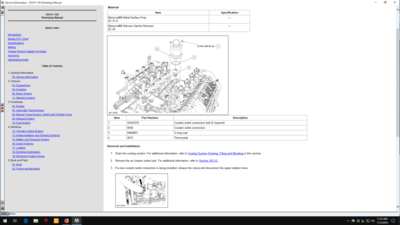

Next, without seeing all the relevant stuff with my own eyes, I’d replace both gasket and T-stat; if you still have the old one, maybe that would work. I’d make sure the surface areas are clean, magnifying glass inspection, razor scrape and solvent. Clean and dry with alcohol, carefully reassemble. Hand tighten the bolts only.

stop. obtain adult beverage and confirm the torque values for these 2 bolts.

Also, confirm these bolts are not torque to yield; that is, not supposed to be reused. I’ve never seen one of these being reused cause a problem, but others on the internet proclaim otherwise and warn of dire consequences if you do.

On the off chance these are one use bolts, get replacements before actual truck use.

Write the torque down on a post it, take the post it, adult beverage and torque wrench to the truck and gradually tighten both bolts to the setting. I realize you probably know all this, but on the off chance something got missed - maybe you made a field expedient repair, who knows.

Once finally torqued with requisite new-ish and cleaned parts, finish adult beverage and retest by starting the truck. let it warm and observe. No need to go anywhere, because even though it’s a small leak here, there’s no sense adding to the potential trouble by finding out the hard way. If the truck passes the driveway smoke test, figuratively of course, take it for a drive where you’re sure to get the temps up. Either spirited driving or haul some cargo.

Good luck.